Reservoir capacity

Refill level

Specification and color of fluid

Correct position of all actuating cylinders during

filling

Other information considered necessary during

the filling of the reservoir

NOTE: After opening a can of hydraulic fluid, the

entire contents should be poured into the fill stand or

servicing unit immediately. This will prevent the fluid

from absorbing dust and grit from the air. Aviation

Hydraulics Manual, NAVAIR 01-1A-l7, requires that

any remaining fluid left in the hydraulic fluid

container, after servicing a fill stand/servicing unit, be

discarded, and that the empty fluid container be

destroyed immediately and not used to store or handle

other fluids.

Q13. Define viscosity.

Q14.

What scale is used by both the Navy and the Air

Force to determine oil viscosity?

Q15. What is the military specification number for the

hydraulic fluid presently used in the hydraulic

systems of all naval aircraft?

Q16.

What should be done with the fluid remaining in

the can after filling a servicing unit?

PNEUMATIC SERVICING

Landing gear struts, hydraulic accumulators, and

various air storage bottles found on most naval aircraft

must be serviced with compressed air or nitrogen.

These components are serviced by Aviation Structural

Mechanics (AMs). You should refer to the applicable

training manuals and technical manuals for in-depth

discussions of the servicing of rate-peculiar

components.

Servicing Air Storage Bottles

Nitrogen and air storage bottles are used on some

aircraft for various emergency operations. These

bottles are necessary for the safe operation of the

aircraft and the safety of the crew. Air storage bottles

are used for such functions as emergency brakes,

emergency landing gear extension, and emergency

canopy operation. Some aircraft have a pneumatic

system that will maintain the required pressure in these

bottles while in flight. However, most of these

pneumatic systems require servicing on the ground

with an external source of high-pressure air or nitrogen

before each flight.

5-11

Air storage bottles and accumulators are serviced

similarly. Most air bottles have an air filler valve and

a pressure gauge. They usually require higher

servicing pressures than accumulators. A

high-pressure compressor and other special

equipment, such as the nitrogen booster, must be used

to obtain these higher pressures.

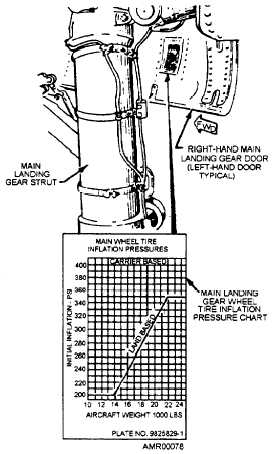

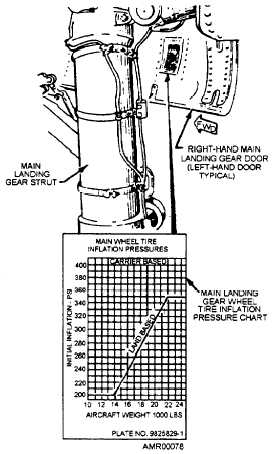

Inflation of Tires

For aircraft tires to perform satisfactorily, the

correct air pressure must be maintained. Aircraft tires

must be inflated to the pressure specified for the type

of operation (ashore or afloat) that the aircraft is

performing and for the gross weight of the aircraft. Air

pressure must be checked daily with an accurate

gauge. Tire inflation data is usually attached to the

aircraft, as shown in figure 5-6. When the aircraft does

not have this plate, you can find the information in the

general information and servicing section of the

applicable MIM.

Overinflation or underinflation of aircraft tires

causes specific problems. Overinflation reduces the

Figure 5-6.—Tire inflation chart.