Figure 1-16.--Compressor surge.

combustion chamber consists of a casing, a

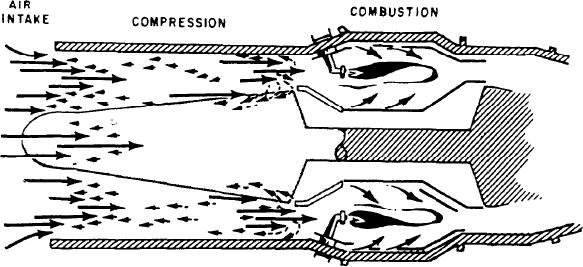

compressor surge. Surge (fig. 1-16) results when

the airflow stalls across the compressor blades;

perforated inner shell, a fuel nozzle, and a device

that is, air is not smoothly compressed into the

for initial ignition (igniter). The number of

combustion and turbine section. Stalling may

combustion chambers used in a GTE varies

widely; as few as one and as many as

occur over a few blades or a section of some

stages. If enough flow is interrupted, pressure

16 combustion chambers have been used in one

GTE. The combustion chamber is the most

may surge back through the compressor. This

efficient component of a GTE. The three types

occurrence can be minor or very severe with

of combustion chambers are the (1) can,

damage to the turbine resulting. If severe

(2) annular, and (3) can-annular. The can-type

disturbance occurs, all the air in the combustor

chamber is used primarily on engines that have

may be used for combustion instead of only the

a centrifugal compressor. The annular and can-

primary air. This would result in a lack of

cooling air (secondary) that may cause extreme

annular types are used on axial-flow compressors.

temperatures which burn the combustor and

turbine section. We will discuss primary and

Can Chamber

secondary air systems later in this chapter.

The can-type combustion chamber has

By a change in the angle of the stators and use

individual liners and cases mounted around the

of bleed valves, smooth airflow through the

axis of the engine. Each chamber (fig. 1-17)

compressor is ensured.

contains a fuel nozzle. This arrangement makes

removing a chamber easy, but it is a bulky

Constant-speed engines, such as those used to

arrangement and makes a structurally weak

drive generators, normally do not use variable

engine. The outer casing is welded to a ring that

stators. They are designed to operate at

directs the gases into the turbine nozzle. Each of

100 percent rpm all the time. Proper fuel

the casings is linked to the others with a short

scheduling and use of bleed air valves are used

tube. This arrangement ensures that combustion

to reduce the probability of compressor surge in

occurs in all the burners during engine start.

these engines.

Inside each of these tubes is a flame tube that joins

an adjacent inner liner.

CLASSIFICATION BY COMBUSTION

Annular Chamber

CHAMBER DESIGN

The annular-type combustion chamber is

The combustion chamber is the component

probably one of the most popular combustion

in which the fuel-air mixture is burned. The

1-16