10. Observe and record capacitance reading

from test stand capacitance gauge in space

provided on Performance Test Sheet. Reading

should be between C(max) and C(min).

11. If the test is not within these limits and

the converter has not been purged in previous

tests, there may be moisture in the sphere. Purge

the converter and refill it with LOX, then repeat

steps 1 through 11.

12. If the converter is still not within limits,

condemn the converter.

13. Secure the tester and disconnect the cables

from the converter and tester. If the converter

passes capacitance test, carefully remove it from

the scales and allow it to remain undisturbed for

1 hour.

EVAPORATION LOSS TEST

(BUILDUP AND SUPPLY MODE)

To perform the evaporation loss test in

the buildup and supply mode, proceed as

follows:

1. At the end of the 1 hour period, gently

place the converter on the scales and record its

weight and the start time in the spaces provided

on section 8 of the Performance Test Sheet.

2. Place the converter assembly aside again

and allow it to remain undisturbed for 24

hours.

3. At the end of the 24-hour period, carefully

replace the converter on the scales.

4. Record the time and weight in the spaces

provided on the Performance Test Sheet. The 24

hour weight loss must be less than 3 pounds.

There should not be a heavy coat of frost on the

sphere.

5. If the weight loss was 3.0 pounds or less,

and there was not excessive frosting of the sphere

assembly, proceed to the flow test. If the

loss was more than 3.0 pounds, proceed to the

EVAPORATION LOSS TEST.

EVAPORATION LOSS TEST

(VENTED MODE)

Maximum allowable loss of LOX in 24 hours

is 5.0 pounds. Minimum allowable loss is defined

as the weight recorded during the buildup and

supply mode minus 0.5 pound (performed only

if converter fails evaporation loss test in buildup

and supply mode).

To perform the evaporation loss test in the

vented mode, proceed as follows:

1. With the converter still on the scales,

attach the test stand fill valve adapter (P/N

59A120-D5-10) to the fill, buildup, and vent valve

on the converter.

WARNING

VENTING A CONVERTER THAT IS IN

A BUILDUP AND SUPPLY MODE

CAUSES A BLAST OF LOX FROM

THE VENT PORT. ENSURE THAT

VENT BLAST IS DIRECTED AWAY

FROM ALL PERSONNEL, AND THAT

ADEQUATE CLOTHING AND FACIAL

PROTECTION ARE WORN.

2. Turn the knurled knob of the adapter in

until it seats. This places the converter in the

vented mode.

3. Record the time and weight in section 9 of

the Performance Test Sheet.

4. Place the converter aside and allow it to

remain undisturbed in the vented mode for 24

hours.

5. At the end of the 24-hour period, carefully

replace the converter on the scales.

6. Record the time and the converter weight

on the Performance Test Sheet. Weight loss in 24

hours should not exceed 5.0 pounds for this test

to be satisfactory.

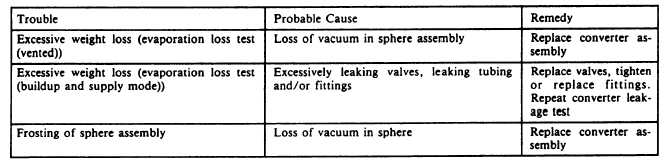

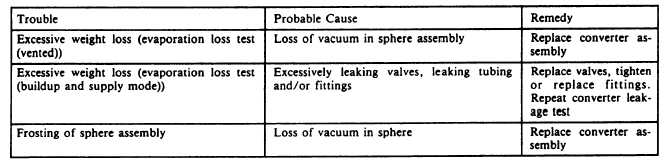

7. If the weight loss is too much, locate the

probable cause by using the troubleshooting chart

in table 12-22.

Table 12-22.—Troubleshooting (Evaporation Loss Test)

12-31