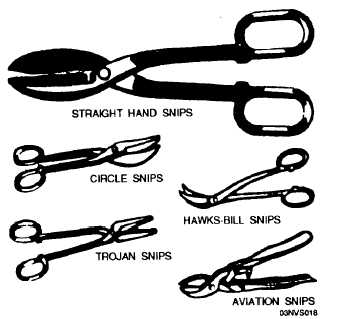

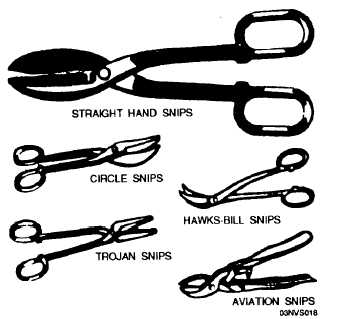

Figure 1-18.-Metal snips.

cutting heavy material, use the rear portion of the

blades. This procedure not only avoids the possibility

of springing the blades but also gives you greater

cutting leverage.

Many snips have small serrations (notches) on the

cutting edges of the blades. These serrations tend to

prevent the snips from slipping backwards when a cut

is being made. Although this feature does make the

actual cutting easier, it mars the edges of the metal

slightly. You can remove these small cutting marks

if you allow proper clearance for dressing the metal to

size. There are many other types of hand snips used

for special jobs, but the snips discussed here can be

used for almost any common type of work.

Cutting Sheet Metal with Snips

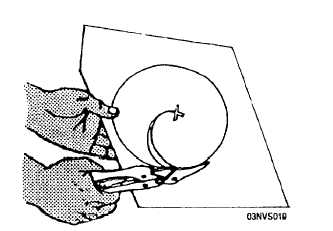

It is hard to cut circles or small arcs with straight

snips. There are snips especially designed for circular

cutting. They are

called CIRCLE SNIPS,

HAWKS-BILL SNIPS, TROJAN SNIPS, and

AVIATION SNIPS (fig. 1-18).

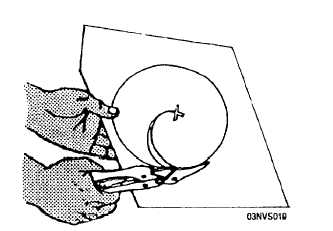

To cut large holes in the lighter gauges of sheet

metal, start the cut by punching or otherwise making

a hole in the center of the area to be cut out. With an

aviation snips, or some other narrow-bladed snips,

make a spiral cut from the starting hole out toward the

scribed circle, as shown in figure 1-19, and continue

cutting until the scrap falls away.

Figure 1-19.-Cutting an inside hole with snips.

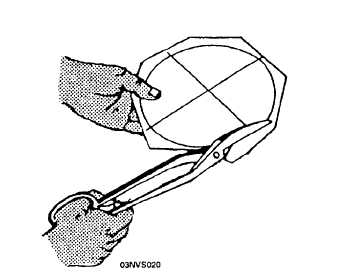

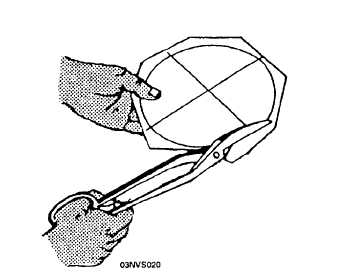

To cut a disk in the lighter gauges of sheet metal,

use a combination snips or a straight-blade snips, as

shown in figure 1-20.

First, cut away any surplus

material outside the scribed circle, leaving only a

narrow piece to be removed by the final cut. Make

the final cut just outside the layout line. This will

permit you to see the scribed line while you are

cutting and will cause the scrap to curl up below the

blade of the snips, where it will be out of the way

while the complete cut is being made.

To make straight cuts, place the sheet metal on a

bench with the marked guideline over the edge of the

bench and hold the sheet down with one hand. With

the other hand, hold the snips so that the flat sides of

the blades are at right angles to the surface of the

Figure 1-20.-Cutting a disk out of sheet metal.

1-13