For long cuts, rotate the blade in the frame so that

the length of the cut is not limited by the depth of the

frame. Hold the work with the layout line close to the

vise jaws, raising the work in the vise as the sawing

proceeds.

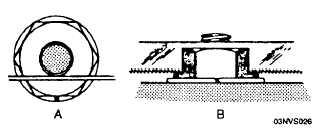

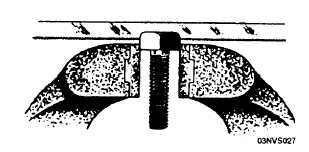

To remove a frozen nut with a hacksaw, saw into

the nut, as shown in figure 1-26, starting the blade

close to the threads on the bolt or stud and parallel to

one face of the nut, as shown in view A. Saw parallel

to the bolt until the teeth of the blade almost reach the

lockwasher.

Lockwashers are hard and will ruin

hacksaw blades, so do not try to saw them. View B

shows when to stop sawing. Then, with a cold chisel

and hammer, remove this one side of the nut

completely by opening the saw kerf.

Put an

adjustable wrench across this new flat and the one

opposite, and again try to remove the frozen nut.

Since very little original metal remains on this one

side of the nut, the nut will either give or break away

entirely and permit its removal.

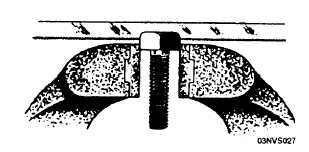

To saw a wide kerf in the head of a cap screw or

machine bolt, fit the hand hacksaw frame with two

blades side by side, and with teeth lined up in the

same direction. With slow, steady strokes, saw the

slot approximately one-third the thickness of the head

of the cap screw, as shown in figure 1-27. Such a

slot will permit subsequent holding or turning with a

screwdriver when it is impossible, due to close

quarters, to use a wrench.

Figure 1-26.-Removing a frozen nut with a hacksaw.

Figure 1-27.-Cutting a wide kerf in the head of a cap

screw or bolt.

Hacksaw Safety

The main danger in using hacksaws is injury to

your hand if the blade breaks. The blade will break

if too much pressure is applied, when the saw is

twisted, when the cutting speed is too fast, or when

the blade becomes loose in the frame. Additionally,

if the work is not tight in the vise, it will sometimes

slip, twisting the blade enough to break it.

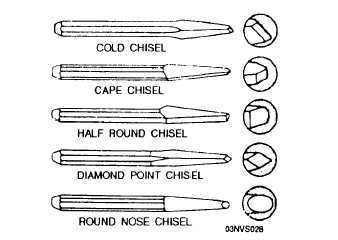

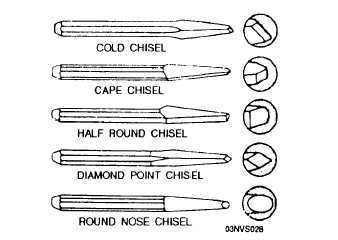

CHISELS

Chisels are tools that can be used for chipping or

cutting metal. They are made from a good grade of

tool steel and have a hardened cutting edge and

beveled head. Chisels are classified according to the

shape of their points, and the width of the cutting

edge denotes their size. The most common shapes of

chisels are the flat (cold chisel), cape, round nose, and

diamond point (fig. 1-28).

The type of chisel most commonly used is the flat

cold chisel, which serves to cut rivets, split nuts, chip

castings, and cut thin metal sheets. The cape chisel is

used for special jobs like cutting keyways, narrow

grooves, and square corners. Round-nose chisels

make circular grooves and chip inside corners.

Finally, the diamond-point is used for cutting

V-grooves and sharp corners.

As with other tools, there is a correct technique

for using a chisel. Select a chisel that is large enough

for the job. Be sure to usc a hammer that matches the

chisel; that is, the larger the chisel, the heavier the

hammer. A heavy chisel will absorb the blows of a

light hammer and will do virtually no cutting.

Figure 1-28-Types of points on metal-cutting chisels.

1-16