Remember that the selection of grades of abrasive

cloth, the application of oil, and the cleaning between

grades applies to polishing, regardless of how the

cloth is held or used.

Care of Files

A new file should be broken in carefully by using

it first on brass, bronze, or smooth cast iron. Just a

few of the teeth will cut at first, so use a light

pressure to prevent tooth breakage. Do not break in

a new file by using it first on a narrow surface.

Protect the file teeth by hanging your files in a

rack when they are not in use or by placing them in

drawers with wooden partitions. Your files should not

be allowed to rust – keep them away from water and

moisture. Avoid getting the files oily. Oil causes a

file to slide across the work and prevents fast, clean

cutting. Files that you keep in your toolbox should be

wrapped in paper or cloth to protect their teeth and

prevent damage to other tools.

Never use a file for prying or pounding. The tang

is soft and bends easily.

The body is hard and

extremely brittle. Even a slight bend or a fall to the

deck may cause a file to snap in two. Do not strike

a file against the bench or vise to clean it – use a file

card.

Safety

Never use a file unless it is equipped with a

tight-fitting handle.

If you use a file without the

handle and it bumps something or jams to a sudden

stop, the tang may be driven into your hand. To put

a handle on a file tang, drill a hole in the handle,

slightly smaller than the tang. Insert the tang end, and

then tap the end of the handle to scat it firmly. Make

sure you get the handle on straight.

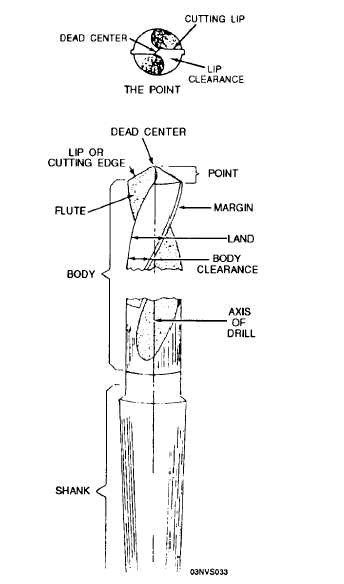

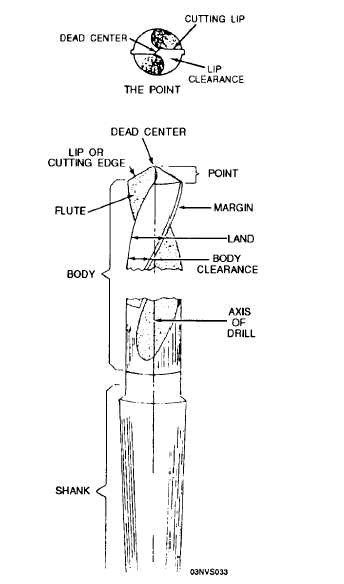

TWIST DRILLS

Making a hole in a piece of metal is generally a

simple operation, but in most cases an important,

precise job. A large number of different tools and

machines have been designed so that holes may be

made speedily, economically, and accurately in all

kinds of material.

To be able to use these tools efficiently, it is

important that you become acquainted with them. The

most common tool for making holes in metal is the

twist drill. It consists of a cylindrical piece of steel

with spiral grooves.

One end of the cylinder is

pointed, while the other end is shaped so that it may

be attached to a drilling machine. The grooves,

usually called FLUTES, may be cut into the steel

cylinder, or the flutes may be formed by twisting a

flat piece of steel into a cylindrical shape.

The principal parts of a twist drill are the body,

the shank, and the point (fig. 1-33). The dead center

of a drill is the sharp edge at the extreme tip end of

the drill. It is formed by the intersection of the

cone-shaped surfaces of the point and should always

be the exact center of the axis of the drill. The point

of the drill should not be confused with the dead

center. The point is the entire cone-shaped surface at

the end of the drill.

Figure 1-33.-Twist drill nomenclature.

1-21