machine shops.

The other type (Bristol) is used

infrequently.

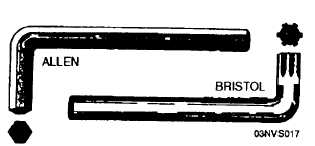

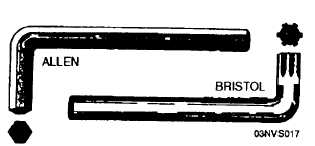

Recessed-head screws usually have a hex-shaped

(six-sided) recess. To remove or tighten this type of

screw requires a special wrench that will fit in the

recess. This wrench is called an Allen-type wrench.

Allen wrenches are made from hexagonal L-shaped

bars of tool steel (fig. 1-17). They generally range in

size up to 3/4 inch.

When using the Allen-type

wrench, make sure you use the correct size to prevent

rounding or spreading the head of the screw. A snug

fit within the recessed head of the screw is an

indication that you have the correct size.

The Bristol wrench is made from round stock. It

is also L-shaped, but one end is fluted to fit the flutes

or little splines in the Bristol setscrew (fig. 1-17).

SAFETY RULES FOR WRENCHES

There are a few basic rules that you should keep

in mind when using wrenches. They are as follows:

Always use a wrench that fits the nut

properly.

Keep wrenches clean and free from oil.

Otherwise they may slip, resulting in possible serious

injury to you or damage to the work.

Do not increase the leverage of a wrench by

placing a pipe over the handle. Increased leverage

may damage the wrench or the work.

Provide some sort of kit or case for all

wrenches. Return them to the case at the completion

of each job. This saves time and trouble and aids

selection of tools for the next job. Most important, it

eliminates the possibility of leaving them where they

can cause injury to personnel or damage to equipment.

Determine which way a nut should be turned

before trying to loosen it. Most nuts are turned

counterclockwise for removal.

This may seem

obvious, but even experienced people have been

observed straining at the wrench in the tightening

direction when they wanted to loosen the nut.

Learn to select your wrenches to fit the type

of work you are doing. If you are not familiar with

these wrenches, make arrangements to visit a shop

that has most of them, and get acquainted.

Figure 1-17.-Allen- and Bristol-type wrenches.

METAL-CUTTING TOOLS

Many types of metal-cutting tools are used by

skilled mechanics of all ratings. As you become

better acquainted with the ABE rating, you will

probably discover many tools that you use for cutting

metal that are not described in this text. In this text,

only the basic hand metal-cutting tools will be

considered.

SNIPS AND SHEARS

Snips and shears are used for cutting sheet metal

and steel of various thicknesses and shapes.

Normally, the heavier or thicker materials are cut by

shears.

One of the handiest tools for cutting light (up to

1/16-inch thick) sheet metal is the hand snip (tip

snips).

The STRAIGHT HAND SNIPS, shown in

figure 1-18, have blades that are straight and cutting

edges that are sharpened to an 85-degree angle. Snips

like this can be obtained in different sizes, ranging

from the small, 6-inch, to the large, 14-inch, snip. Tin

snips will also work on slightly heavier gauges of soft

metals, such as aluminum alloys.

Snips will not remove any metal when a cut is

made. There is danger, though, of causing minute

metal fractures along the edges of the metal during the

shearing process. For this reason, it is better to cut

just outside the layout line. This procedure will allow

you to dress the cutting edge while keeping material

within required dimensions.

Cutting extremely heavy gauge metal always

presents the possibility of springing the blades. Once

the blades are sprung, hand snips are useless. When

1-12