Most soft-faced hammers have heads that can be

replaced as the need arises. Lead-faced hammers, for

instance, quickly become battered and must be

replaced, but have the advantage of striking a solid,

heavy nonrebounding blow that is useful for such jobs

as driving shafts into or out of tight holes. If a

soft-faced hammer is not available, the surface to be

hammered may be protected by covering it with a

piece of soft brass, copper, or hard wood.

Using Hammers

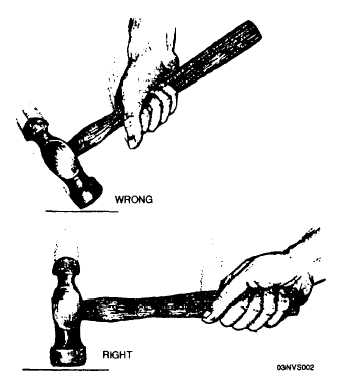

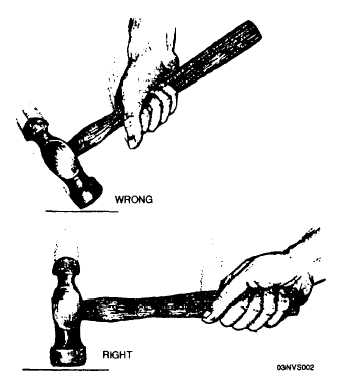

Simple as the hammer is, there is a right and a

wrong way of using it.

(See fig. 1-2.) The most

common fault is holding the handle too close to the

head. This is known as choking the hammer, and

reduces the force of the blow. It also makes it harder

to hold the head in an upright position. Except for

light blows, hold the handle close to the end to

increase leverage and produce a more effective blow.

Hold the handle with the fingers underneath and the

thumb along side or on top of the handle. The thumb

should rest on the handle and never overlap the

fingers. Try to hit the object with the full force of the

hammer. Hold the hammer at such an angle that the

face of the hammer and the surface of the object being

hit will be parallel. This distributes the force of the

blow over the full face and prevents damage to both

the surface being struck and the face of the hammer.

MALLETS AND SLEDGES

The mallet is a short-handled tool used to drive

wooden-handled chisels, gouges, and wooden pins, or

to form or shape sheet metal where hard-faced

hammers would mar or damage the finished work.

Mallet heads are made from a soft material, usually

wood,

rawhide,

or rubber.

For example, a

rubber-faced mallet is used for knocking out dents in

an automobile. It is cylindrically shaped with two flat

driving faces that are reinforced with iron bands. (See

fig. 1-1.) Never use a mallet to drive nails, screws, or

any other object that can damage the face of the

mallet.

The sledge is a steel-headed, heavy-duty driving

tool that can be used for a number of purposes.

Short-handled sledges are used to drive driftpins, and

large nails, and to strike cold chisels and small

hand-held rock drills. Long-handled sledges are used

to break rock and concrete, to drive spikes or stakes,

and to strike rock drills and chisels.

made of a

Figure 1-2.-Striking a surface.

The head of a sledge is generally

high-carbon steel and may weigh from 2 to 16

pounds. The shape of the head will vary according to

the job for which the sledge is designed.

MAINTENANCE OF STRIKING

TOOLS

Hammers, sledges, or mallets should be cleaned

and repaired if necessary before they are stored.

Before using them, make sure the faces are free from

oil or other material that would cause the tool to

glance off nails, spikes, or stakes. The heads should

be dressed to remove any battered edges.

Never leave a wooden or rawhide mallet in the

sun, as it will dry out and may cause the head to

crack. A light film of oil should be left on the mallet

to maintain a little moisture in the head.

The hammer handle should always be tight in the

head. If it is loose, the head may fly off and cause an

injury.

1-3