tools results in improper maintenance. Improper maint

enance results in damage to equipment and possible

injury or death to you or others.

SAFE MAINTENANCE PRACTICES–Always

avoid placing tools on or above machinery or an

electrical apparatus.

Never leave tools unattended

where machinery or aircraft engines are running.

NEVER USE DAMAGED TOOLS – A battered

screwdriver may slip and spoil the screw slot, damage

other parts, or cause painful injury. A gauge strained

out of shape will result in inaccurate measurements.

Remember, the efficiency of craftsmen and the

tools they use are determined to a great extent by the

way they keep their tools.

Likewise, they are

frequently judged by the manner in which they handle

and care for them.

Anyone watching skilled

craftsmen at work notices the care and precision with

which they use the tools of their trade.

The care of hand tools should follow the same

pattern as for personal articles; that is, always keep

hand tools clean and free from dirt, grease, and

foreign matter. After use, return tools promptly to

their proper place in the toolbox. Improve your own

efficiency by organizing your tools so that those used

most frequently can be reached easily without digging

through the entire contents of the box.

Avoid

accumulating unnecessary junk.

STRIKING TOOLS

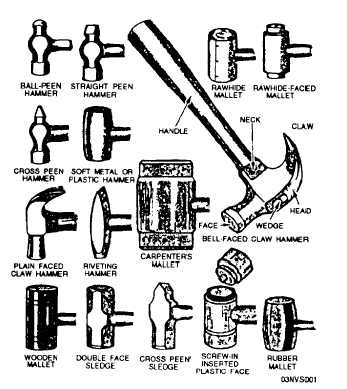

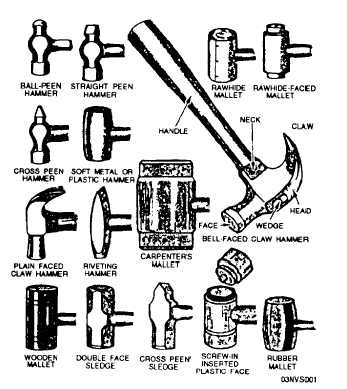

Hammers, mallets, and sledges are used to apply

a striking force. The tool you select (fig. 1-1) will

depend upon the intended application.

HAMMERS

A toolkit for nearly every rating in the Navy

would not be complete without at least one hammer.

In most cases, two or three are included, since they

are designated according to weight (without the

handle) and style or shape. The shape will vary

according to the intended work.

Machinists’ Hammers

Machinists’ hammers are mostly used by

who work with metal or around machinery.

people

These

hammers are distinguished from carpenter hammers by

a variable-shaped peen, rather than a claw, at the

Figure 1-1.-Hammers mallets, and sledges.

opposite end of the face (fig. 1-1). The ball-peen

hammer is probably most familiar to you.

The ball-peen hammer, as its name implies, has a

ball that is smaller in diameter than the face. It is

therefore useful for striking areas that are too small

for the face to enter.

Ball-peen hammers are made in different weights,

usually 4, 6, 8, and 12 ounces and 1, 1 1/2, and 2

pounds. For most work a 1 1/2 pound and a 12-ounce

hammer will suffice.

However, a 4- or 6-inch

hammer will often be used for light work such as

tapping a punch to cut gaskets out of sheet gasket

material.

Machinists’ hammers may be further divided into

hard-face and soft-face classifications. The hard-faced

hammer is made of forged tool steel, while the

soft-faced hammers have a head made of brass, lead,

or a tightly rolled strip of rawhide. Plastic-faced

hammers or solid plastic hammers with a lead core for

added weight are becoming increasingly popular.

Soft-faced hammers (fig. 1-1) should be used

when there is danger of damaging the surface of the

work, as when poundind on a machined surface.

1-2