SAFETY PRECAUTIONS

Hammers are dangerous tools when used

carelessly and without consideration. Practice will

help you learn to use a hammer properly.

Some important things to remember when using

a hammer or mallet follow:

Do not use a hammer handle for bumping

parts in assembly, and never use it as a pry bar. Such

abuses will cause the handle to split, and a split

handle can produce bad cuts or pinches. When a

handle splits or cracks, do not try to repair it by

binding with string, wire, or tape. Replace it.

Make sure the handle fits tightly on the head.

Do not strike a hardened steel surface with a

steel hammer. Small pieces of steel may break off

and injure someone in the eye or damage the work.

However, it is permissible to strike a punch or chisel

directly with a ball-peen hammer, because the steel in

the heads of punches and chisels is slightly softer than

that of the hammerhead.

WRENCHES

A wrench is a basic tool that is used to exert a

twisting force on bolt heads, nuts, studs, and pipes.

The special wrenches designed to do certain jobs are,

in most cases, variations of the basic wrenches that

are described in this section.

The best wrenches are made of chrome vanadium

steel. Wrenches made of this material are lightweight

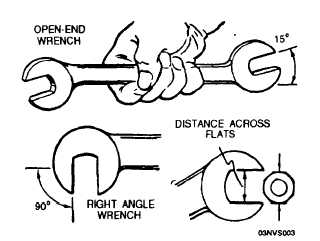

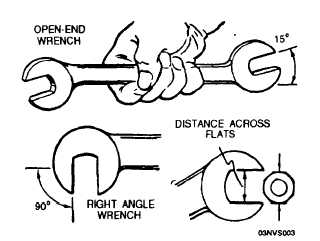

Figure 1-3.-Open-end wrenches.

and almost unbreakable.

This is an expensive

material, however, so the most common wrenches

found in the Navy are made of forged carbon steel or

molybdenum steel. These latter materials make good

wrenches, but they are generally built a little heavier

and bulkier to achieve the same degree of strength as

chrome vanadium steel.

The size of any wrench used on bolt heads or nuts

is determined by the size of the opening between the

jaws of the wrench.

The opening of a wrench is

manufactured slightly larger than the bolt head or nut

that it is designed to fit. Hex-nuts (six-sided) and

other types of nut or bolt heads are measured across

opposite flats (fig. 1-3). A wrench that is designed to

fit a 3/8-inch nut or bolt usually has a clearance of

from 5 to 8 thousandths of an inch. This clearance

allows the wrench to slide on and off the nut or bolt

with a minimum of “play.” If the wrench is too large,

the points of the nut or bolt head will be rounded and

destroyed.

There are many types of wrenches. Each type is

designed for a specific use. Let’s discuss some of

them.

OPEN-END WRENCHES

Solid, nonadjustable wrenches with openings in

one or both ends are called open-end wrenches. (See

fig. 1-3.) Usually they come in sets of from 6 to 10

wrenches, with sizes ranging from 5/16 to 1 inch.

Wrenches with small openings are usually shorter than

wrenches with large openings. This proportions the

lever advantage of the wrench to the bolt or stud and

helps prevent wrench breakage or damage to the bolt

or stud. One exception exists.

Hydraulic piping installations for catapult and

arresting gear are often in close spaces.

During

certain phases of hydraulic maintenance it may be

impossible to swing an ordinary wrench because of its

length. Ordinary wrenches that are normally available

increase in length as their size increases. Thus, when

a large-size wrench is needed, the length of the

wrench sometimes prevents its use, due to the space

available to swing the wrench. The Bonney wrench,

shown in figure 1-4, is an open-end wrench that may

be used to great advantage because of its thickness

and short length. This wrench is normally procured

in the larger sizes, although it is available in a range

of sizes to fit most hydraulic fittings.

1-4