CARE OF HAND TOOLS

Tools are expensive; tools are vital equipment.

When the need for their use arises, common sense

plus a little preventive maintenance prolongs their

usefulness. The following precautions for the care of

tools should be observed:

Clean tools after each use. Oily, dirty, and

greasy tools are slippery and dangerous to use.

NEVER hammer with a wrench.

NEVER leave tools scattered about. When

they are not in use, stow them neatly on racks or in

toolboxes.

Apply a light film of oil after cleaning to

prevent rust on tools.

INVENTORY tools after use to prevent loss.

PERSONAL SAFETY EQUIPMENT

To protect you from danger, protective equipment

such as safety shoes, goggles, hard hats, and gloves

are issued. The use of this equipment is mandatory

on certain jobs. Their use is a MUST, and there is no

question about that. Be sure to USE THEM on any

job WHERE they are REQUIRED. They can protect

you from a lot of harm.

SAFETY SHOES

Some safety shoes are designed to limit damage to

your toes from falling objects. A steel plate is placed

in the toe area of such shoes so that your toes are not

crushed if an object impacts there.

Other safety shoes are designed for use where

danger from sparking could cause an explosion. Such

danger is minimized by elimination of all metallic

nails and eyelets and by the use of soles that do not

cause static electricity.

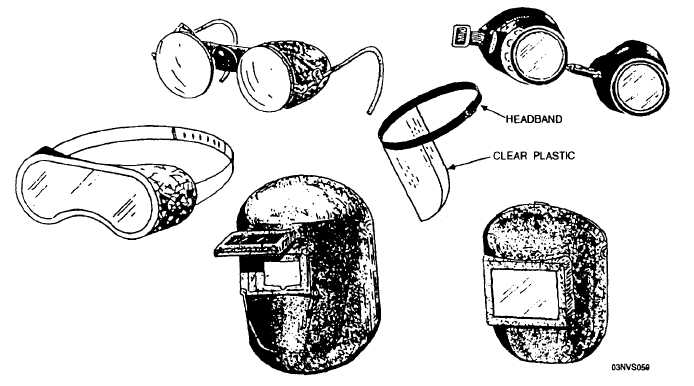

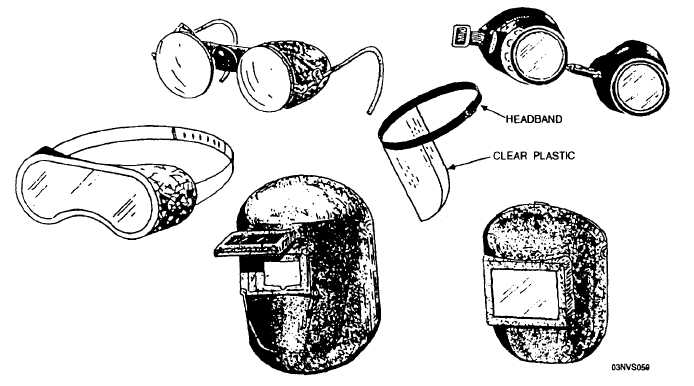

GOGGLES

Proper eye protection is of the utmost importance

for all personnel. Eye protection is necessary because

of hazards posed by infrared and ultraviolet radiation,

or by flying objects such as sparks, globules of molten

metal, or chipped concrete and wood. These hazards

are everpresent during welding, cutting, soldering,

chipping, grinding, and a variety of other operations.

It is IMPERATIVE for you to use eye protection

devices, such as helmets, face shields, and goggles

(fig. 1-59), during eye-hazard operations.

Figure 1-59.-Eye-protection devices.

1-35