PORTABLE PNEUMATIC

POWER TOOLS

Portable pneumatic power tools are tools that look

much the same as electric power tools but use the

energy of compressed air instead of electricity.

Because of the limited outlets for compressed air

aboard ship and shore stations, the use of pneumatic

power tools is not as widespread as electric tools.

Portable pneumatic tools are used most around a shop

where compressed air outlets are readily

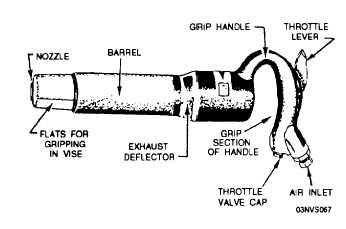

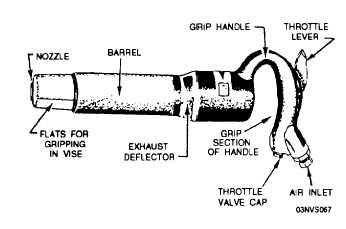

PNEUMATIC CHIPPING HAMMER

The pneumatic chipping hammer

accessible.

(fig. 1-67)

consists basically of a steel piston that is reciprocated

(moved backward and forward alternately) in a steel

barrel by compressed air. On its forward stroke the

piston strikes the end of the chisel, which is a sliding

fit in a nozzle pressed into the barrel. The rearward

stroke is cushioned by compressed air to prevent any

metal-to-metal contact. Reciprocation of the piston is

automatically controlled by a valve located on the rear

end of the barrel. Located on the rear end of the

barrel is a grip handle, containing a throttle valve.

The pneumatic hammer may be used for beveling;

caulking or beading operations and for drilling in

brick, concrete, and other masonry.

Chipping hammers should not be operated without

safety goggles, and all other persons in the immediate

vicinity of the work should wear goggles.

While working, never point the chipping hammer

in such a direction that other personnel might be

struck by an accidentally ejected tool. When chipping

alloy steel or doing other heavy work, it is helpful to

Figure 1-67.-Pneumatic chipping hammer.

dip the tool in engine lubricating oil about every 6

inches of the cut and make sure the cutting edge of

the tool is sharp and clean. This will allow faster and

easier cutting and will reduce the possibility of the

tool breaking.

When nearing the end of a cut, ease off on the

throttle lever to reduce the intensity of the blows.

This will avoid any possibility of the chip or tool

flying.

If for any reason you have to lay the chipping

hammer down, always remove the attachment tool

from the nozzle. Should the chipping hammer be

accidentally started when the tool is free, the blow of

the piston will drive the tool out of the nozzle with

great force and may damage equipment or injure

personnel.

ROTARY AND NEEDLE

IMPACT SCALERS

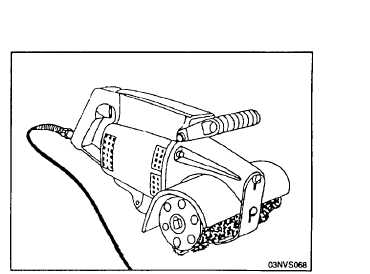

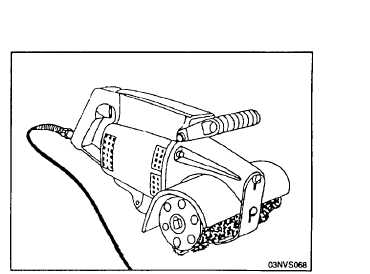

Rotary and needle scalers (figs. 1-68 and 1-69) are

used to remove rust, scale, and old paint from metallic

and masonry surfaces. You must be especially careful

when using these tools since they will “chew” up

anything in their path. Avoid getting the power line

or any part of your body in their way.

The rotary scaling and chipping tool, sometimes

called a “jitterbug,” has a bundle of cutters or chippers

for scaling or chipping (fig. 1-68). In use, the tool is

pushed along the surface to be scaled, and the rotating

chippers do the work. Replacement bundles of cutters

are available when the old ones are worn.

Figure 1-68.- Rotary impact scaler.

1-40