BE SURE YOU ARE NOT DAYDREAMING

when you use the rotary scaler.

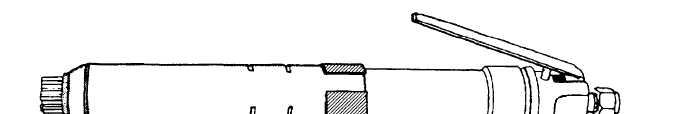

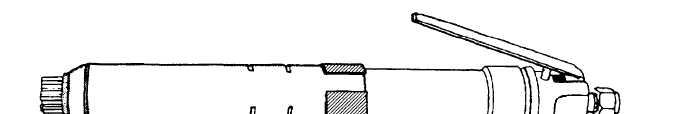

Needle scalers accomplish their task with an

assembly of individual needles impacting on a surface

hundreds of times a minute. The advantage of using

individual needles is that irregular surfaces can be

cleaned readily. See figure 1-69.

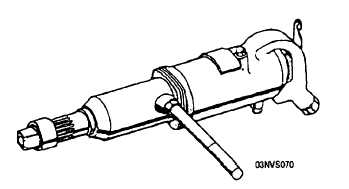

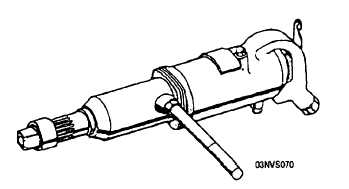

PORTABLE PNEUMATIC

IMPACT WRENCH

The portable pneumatic impact wrench (fig. 1-70)

is designed for installing or removing nuts and bolts.

The wrench comes in different sizes and is classified

by the size of the square anvil on the drive end. The

anvil is equipped with a socket lock, which provides

positive locking of the socket wrenches or

attachments. The wrench has a built-in oil reservoir

and an adjustable air valve regulator, which adjusts

the torque output of the wrench. The torque regulator

reduces the possibility of shearing or damaging

threads when installing nuts and bolts to their required

tension.

Nearly all pneumatic wrenches operate most

efficiently on an air pressure range of 80 to 90 psi. A

variation in excess of plus or minus 5 pounds is

serious.

Lower pressure causes a decrease in the

driving speeds, while higher pressure causes the

wrench to overspeed with subsequent abnormal wear

of the motor impact mechanisms.

The throttle lever, located at the rear of the

pneumatic wrench, provides the means for starting and

stopping the wrench.

Depressing the throttle lever

starts the wrench in operation. Upon release, the lever

rises to its original position, stopping the wrench.

The valve stem is seated beneath the pivot end of

the throttle lever. Most wrenches have a window cut

in the throttle lever so that the markings on the upper

surface of the valve stem will be visible. Two letters,

F and R, have been engraved on the head of the valve

stem to indicate the forward (clockwise) and reverse

(counterclockwise) rotation of the anvil. To change

from forward to reverse rotation, or vice versa, turn

the valve stem 180° until the desired marking is

visible through the window in the throttle lever.

When the valve stem is in proper position, the valve

stem pin engages a recess on the underside of the

valve stem, preventing accidental turning of the stem.

The air valve regulator is located at the bottom

and towards the rear of the wrench.

Using a

screwdriver and altering the setting of the air regulator

up to 90°, either to the right or left, reduces the torque

from full power to zero power.

Before operating the pneumatic impact wrench,

make sure the socket or other attachment you are

using is properly secured to the anvil. It is always a

good idea to operate the wrench free of load in both

forward and reverse directions to see that it operates

properly.

Check the installation of the air hose to

make sure it is in accordance with the manufacturer’s

recommendation.

Figure 1-70.-Pneumatic impact wrench.

1-41

Figure 1-69.-Needle impact scaler.