the threaded hole. Tap extractors are used to remove

broken taps (fig. 1-44, view A).

Screw extractors (view B) are straight, with

spiraling flutes at one end.

These extractors are

available in sizes to remove broken screws having

1/4- to 1/2-inch outside diameters (ODs). Spiral

tapered extractors are sized to remove screws and

bolts from 3/16 inch to 2 1/8 inches OD.

Most sets of extractors include twist drills and a

drill guide. Tap extractors are similar to the screw

extractors and are sized to remove taps ranging from

3/16 inch to 2 1/8 inches OD.

To remove a broken screw or tap with a spiral

extractor, first drill a hole of proper size in the screw

or tap.

The size hole required for each screw

extractor is stamped on it. The extractor is then

inserted in the hole, and turned counterclockwise to

remove the defective component.

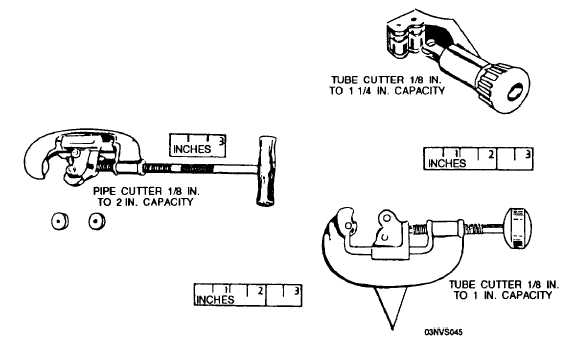

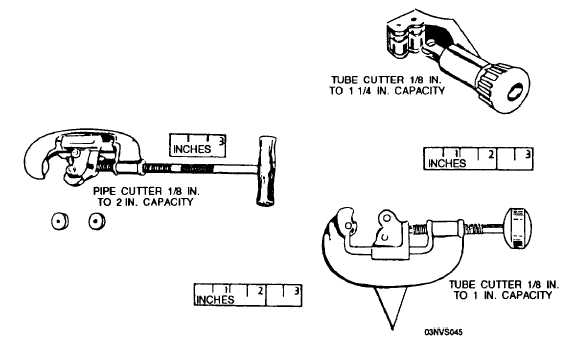

PIPE AND TUBING CUTTERS AND

FLARING TOOLS

Pipe cutters (fig. 1-45) are used to cut pipe made

of steel, brass, copper, wrought iron, or lead. Tube

cutters (fig. 1-45) are used to cut tubing made of iron,

steel, brass, copper, or aluminum.

The essential

difference between pipe and tubing is that tubing has

considerably thinner walls. Flaring tools (fig. 1-46)

are used to make flares in the ends of tubing.

Two sizes of hand pipe cutters are generally used

in the Navy. The No. 1 pipe cutter has a cutting

capacity of 1/8 inch to 2 inches, and the No. 2 pipe

cutter has a cutting capacity of 2 to 4 inches. The

pipe cutter (fig. 1-45) has a special alloy-steel cutting

wheel and two pressure rollers, which are adjusted and

tightened by turning the handle.

Most TUBE CUTTERS closely resemble pipe

cutters, except that they are of lighter construction. A

hand screw feed tubing cutter of l/8-inch to 1

l/4-inch capacity (fig. 1-45) has two rollers with

cutouts located off center so that cracked flares may

be held in them and cut off without waste of tubing.

It also has a retractable cutter blade, which is adjusted

by turning a knob. The other tube cutter shown is

designed to cut tubing up to and including 1 inch OD.

Rotation of the triangular portion of the tube cutter

within the tubing will eliminate any burrs.

FLARING TOOLS (fig. 1-46) are used to flare

soft copper, brass, or aluminum. The single flaring

1-27

Figure 1-45.-Pipe and tubing cutters.