designed to act as a single spring by means of rods

(3) that pass through each set of springs and end in

eyed terminals (6). The inboard ends of the rods

are bolted to clevises (2), which are welded to an

equalizing plate (l).

The plate has a threaded

adjustable rod that is secured to the ship’s structure

to hold the inboard ends of the spring unit. The

outboard ends of the rods are bolted to a similar

plate, which has a welded clevis outboard, through

which is bolted the eyed terminal of the

counterbalancing spring cable. The cable (7) runs

through two sheaves and is then bolted through its

terminal to the actuator arm of the barricade

stanchion, below the point of attachment for the

cylinder.

When the stanchion is lowered by the cylinder,

the sets of springs are uniformly compressed and

resist the force of the descent, and cushions its fall

against the deck. Raising the stanchion slackens the

spring cable and decompresses the spring, but this

release of compression has no appreciable effect on

raising the stanchion.

STANCHION LATCH

Stanchion latches are used to secure the

stanchions to the deck in their DOWN position.

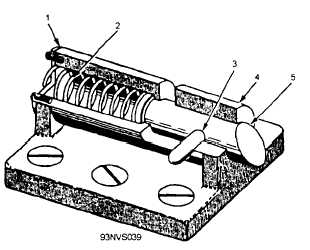

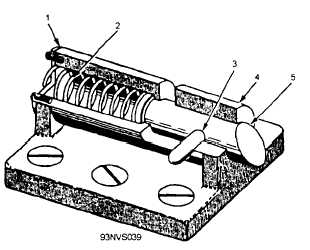

Stanchion latches (fig. 3-39) are spring-loaded

latches bolted to the subdeck and provided with a

slotted frame, designed to allow the latch (5) to bc

retracted against the force of a spring (2), and

turned to lock the latch open. When the stanchion

1. End plate

4. Body

2. Spring

5. Latch

3. Pin

Figure 3-39.—Stanchion latch assembly.

is lowered, the latch may be engaged in a hole

provided in the stanchion, and a spring will hold the

latch in.

POWER PACKAGE

The power package (fig. 3-40) provides and

maintains the fluid pressure required by the

hydraulic cylinders to raise and lower the barricade

stanchions. It consists of a base weldment, gravity

tank assembly (7), control panel assembly (8),

accumulator (1), motor controller (9), pump (2),

electric motor, electrical system, and piping system.

The gravity tank assembly has a capacity of

approximately 100 gallons and is the fluid reservoir

in the power package assembly. Displaced fluid

from the cylinder assemblies is returned to the

gravity tank, and from there it is pumped back to

the accumulator. The gravity tank is welded steel,

closed at the top and bottom by flat plates. The top

cover plate has an access hole, which is covered by

a cap plate and gasket held in place by bolts.

Tapped bosses welded to the cap plate are for

breather vents. A Iiquid-level gauge is connected to

the side of the gravity tank. An indicator plate is

attached to the tank at the level gauge to show the

proper fluid level.

The control panel assembly (fig. 3-41) is

attached to the gravity tank by four bolts.

The panel consists of the panel frame (1), two

piping support brackets (9), accumulator pressure

gauge (6), pressure sensing switch (7), gauge valve

(3), air-charging valve (5), vent valve (2), air supply

valve

(4), caution plate (8), and operating

instruction plate (10). Necessary copper tubing and

sil-braze fittings

connect the panel to the

accumulator assembly, to a ship’s exhaust line, and

to the ship’s high-pressure air supply line. The

accumulator pressure gauge (6) is used to indicate

pressures ranging from 0 to 2,000 psi in the

accumulator.

The pressure-sensing switch (7) is a piston type,

contained in a splashproof housing. It is connected

to the pressure line from the accumulator with a

threaded adapter and a coil of tubing between the

adapter and tee in the pressure line. The function

of the pressure-sensing switch is to maintain

accumulator pressure between 1,250 psi and 1,500

psi. It does this by opening or closing to stop or

start the pump motor. The pressure switch operates

3-42