SHEAVE DAMPER

Because of the high engaging velocities of

modern carrier-based aircraft, cable tension and

vibration would be excessive unless eased by the

shock absorption provided by the sheave damper.

The sheave damper reduces peak cable tension and

lessens cable vibration.

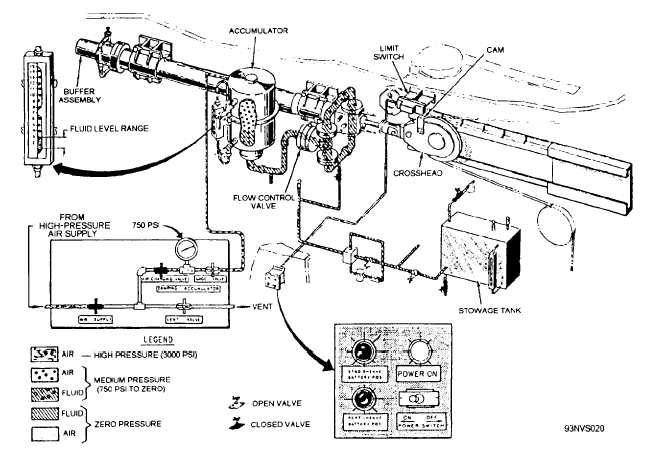

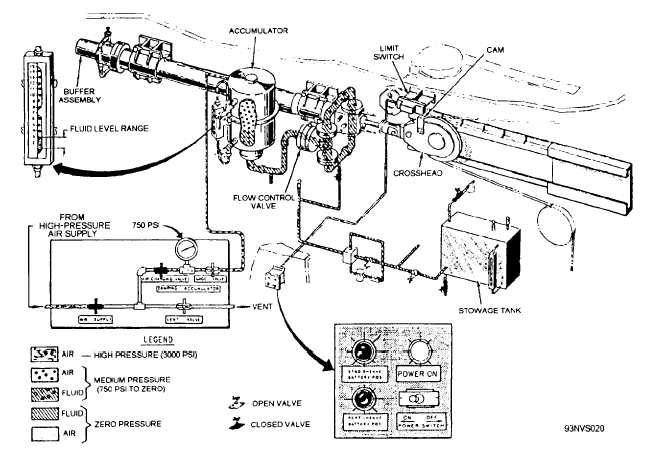

In figure 3-20, a sheave damper assembly is

mounted to the ship’s structure below each port and

starboard retractable or fixed horizontal deck

sheave.

The port and starboard assemblies are

identical; therefore, only one will be discussed.

Description

Each sheave damper assembly consists of a

movable crosshead assembly, damper cylinder

assembly, damper piston, damper accumulator and

fluid piping, buffer assembly, and charging panel.

The system is also equipped with a common fluid

stowage tank, which provides a stowage space for

fluid in the sheave damper assembly while

maintenance is being performed.

The tank is

capable of stowing all the fluid in one sheave

damper installation.

The crosshead assembly consists of one roller

bearing sheave mounted between a steel base plate

and a side plate that are bolted together. A sheave

shaft, mounted through the bottom of the base

plate, is secured to the side plate by a cap and

setscrew. A yoke is bolted between the side plate

and the base plate and provides a means of

connecting the crosshead to a clevis that is screwed

onto the end of a piston rod. The crosshead rides

in a track mounted in a horizontal position on the

bulkhead. Phcnolic slippers, at all four corners of

the base plate, provide a bearing surface between

the crosshead and the track.

Attached to the

crosshead is a cam that actuates a limit switch when

the crosshead is fully retracted and causes a green

light to light at the deckedge control station. This

indicates to the deckedge operator that the sheave

damper is in its BATTERY position.

The damper cylinder assembly is secured to the

ship’s structure by brackets, which are welded to the

bulkhead and bolted to the cylinder. A cylinder cap

Figure 3-20.—Sheave damper installation.

3-24