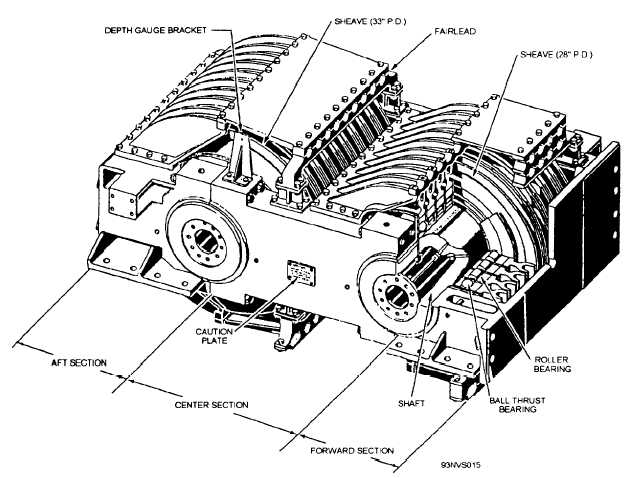

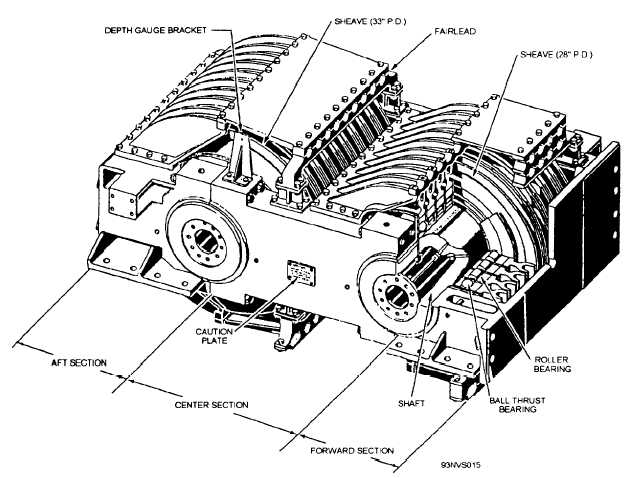

NOTE

The 28-inch pitch diameter sheave

containing the ball thrust bearing is not

lubricated with the automatic lubricating

system. The ball thrust bearing eliminates

the need for constant lubrication.

Lubricating the ball thrust bearing sheave is

accomplished with a manually operated

grease gun after every 20 to 30 arrestments.

(See fig. 3-16 for an illustration of the

automatic lubrication system.)

CABLE ANCHOR DAMPER

The cable anchor damper installation consists of

two identical cable anchor damper assemblies, which

are either deck mounted or overhead mounted (fig.

3-17). Compartment configuration determines how

the units are installed.

The purpose of the cable anchor damper is to

eliminate excessive purchase cable slack between the

crosshead and fixed sheave assembly at the

beginning of the arrestment stroke. Through service

use and experimental testing, it was found that when

this cable slack was taken up by the landing aircraft,

excessive vibrations occurred in the engines. The

cable anchor damper removes this slack as it occurs,

thereby eliminating vibration of the purchase cable.

The cable anchor damper assembly is used with

pendant engines only.

Referring to figure 3-17, note that each cable

anchor damper assembly includes a cylinder that

connects to an operating end head and a cushioning

end head. Piping connects the engine cylinder to

the operating end head through a manifold tee.

Two lines branch from the manifold tee, one to

each damper assembly operating head. Each of

these lines contains a flow control valve. A cover

is placed over the operating piston rod and coupling

3-20

Figure 3-15.—Fixed sheave assembly.