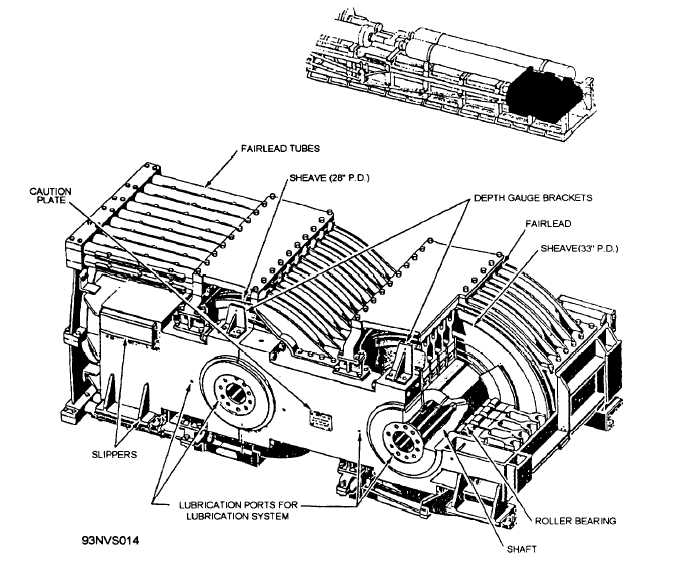

Figure 3-14.–Crosshead assembly.

AUTOMATIC LUBRICATION

SYSTEM

An automatic lubrication system is provided to

ensure that lubricant is automatically provided

between the bonded spacers and bearing pads of the

28-inch pitch diameter and 33-inch pitch diameter

high-speed sheaves of the crosshead and fixed

sheave assembly during arrestment operations

( p e n d a n t e n g i n e s o n l y ) . T h e s h i p ' s

medium-pressure air, reduced to 80 (±5) psi, is

piped to a regulator, which reduceds the air to the

required operating pressure of between 60 and 70

psi. Air is fed through a rubber hose to a pump

mounted on top of a 120-pound drum of lubricant.

Lubricant is pumped from the drum through hoses

to control valves mounted on the engine structure.

These control valves adjust the rate of flow of

lubricant to the high-speed sheaves.

The control valves are operated by plunger

rollers, which are cam-actuated at a set position of

the engine crosshead arrestment stroke. An ounce

of lubricant is pumped to the high-speed sheaves

during the arrestment and the retraction cycles. A

hose reel with a flexible rubber hose is mounted on

the crosshead end of the engine structure, with the

hose connected to metal tubing on the engine

crosshead. As the crosshead moves toward the fixed

sheaves during arrestment, the hose pays out and

spring tension in the hose reel takes up the hose

during retraction. The spring tension on the hose

reel must be 9 pounds (±1/2 pound), with the hose

fully retracted, at all times.

3-19