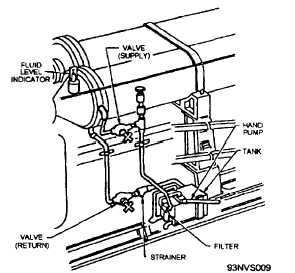

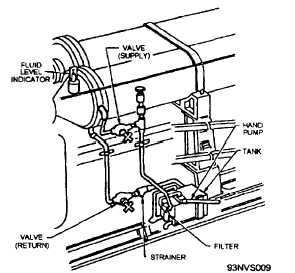

arresting engines, a fluid replenishment system is

provided. See figure 3-9.

The fluid replenishment system consists of a

small hand pump, mounted on the lower engine

frame, that is connected by piping to the engine

accumulator and a 6-gallon stowage tank. If,

because of leakage or fluid contraction while the

engine crosshead is in BATTERY, the fluid-level

indicator reads FILL, the supply valve in the piping

is opened and the hand pump is operated until the

indicator reads BATTERY. A fluid filter is located

in the supply line to filter the fluid being pumped

into the accumulator. If the fluid-level indicator

reads DRAIN, the return valve located in the return

line is opened, and fluid from the accumulator

drains into the replenishment tank. When the

fluid-level indicator reads BATTERY, the return

valve is closed.

FLUID STOWAGE SYSTEM

A fluid stowage system (fig. 3-10) is provided to

stow fluid from the arresting engine during

maintenance and to transfer fluid back to the engine

after maintenance is complete.

Because of the

difference in the fluid capacity of the Mods 2 and 3

engines, the capacity of the fluid stowage systems

differs. The fluid stowage system consists of one

common, steel stowage tank that serves all the

arresting engines installed on a particular ship. It is

equipped with piping valves from the accumulator to

the stowage tank.

The capacity of the fluid stowage tanks is

Mod 2, 600 gallons, and Mod 3, 700 gallons. The

stowage tank is capable of storing all the fluid in the

system of one arresting engine. Ship’s low-pressure

air is used to force the fluid to and from the

stowage tank. A pressure relief valve, which is set

at 120 psi, is provided to prevent excessive pressure

buildup. The relief valve is located on the stowage

tank.

Fluid Cooler

During continuous arresting operations, the

engine fluid temperature rises because of friction of

the fluid moving through the engine, control valve,

and piping. To maintain extended pendant engine

operation, the fluid temperature is reduced by the

fluid cooler.

(See fig. 3-11.) The maximum

operating temperature for all arresting engines is

170°F. Prolonged operation at this temperature

limit is not recommended.

The fluid cooler is mounted in saddles on top of

the engine structure adjacent to the accumulator.

Fluid coolers are used on all Mk 7 arresting

engines serving a pendant engine. Engine fluid, as

it is returned from the accumulator to the main

engine cylinder during retraction of the engine,

flows through the fluid cooler body. Heat from the

engine fluid is transferred to cool service water (salt

water) flowing at 100 gallons per minute through

tubes within the cooler body.

The fluid cooler body is a cylindrical steel shell

with two flanged ends. The body of the cooler has

four equally spaced holes in each end to provide a

means of draining and venting the cooler. These

holes are normally closed with pipe plugs or vent

valves. One end of the cooler has a cooler head

assembly that forms a cap for one end of the body

and provides an inlet for engine fluid coming from

the accumulator. The cooler head assembly is a

disc-shaped steel casting with an opening in the

center, which is flanged to the fluid inlet piping. A

copper annealed gasket is used as a seal between

the cooler head and the body to prevent fluid

leakage. The head is bolted to the body. The

coolant (salt water) flows through a tube assembly

that consists of 107 U-shaped copper tubes

supported inside the cooler body by three circular

baffle plates. A tube head is bolted to the end of

the cooler, opposite of the cooler head. A copper

annealed gasket is used as a seal against fluid

leakage between the tube head and the cooler body.

3-14

Figure 3-9.—Fluid replenishment system.