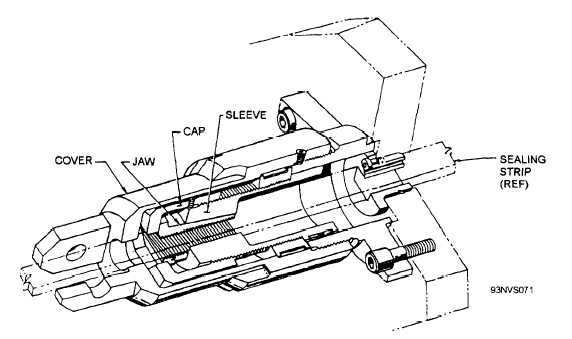

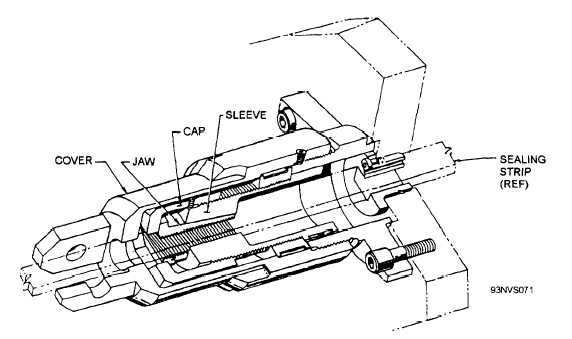

Figure 4-9.—Sealing strip anchor installation.

cylinders. They, in turn, drive the shuttle. Component

parts of each piston assembly are the steam piston, the

barrel, the connector and the strip guide, the piston

guide, and the tapered spear (see fig. 4-6).

The barrel serves as the chassis for the other

components of the assembly. The piston is bolted to the

aft end of the barrel; the piston rings installed on the

piston seal the space between the piston and the

cylinder wall. The cylinder cover segmented seal

assembly acts as an extension of the piston into and

through the cylinder slot. This seal assembly consists of

a housing, three upper seal segments, and six lower seal

segments. The upper seal segments press against the

cylinder covers, and the lower seal segments press

against the sides of the cylinder slot to prevent the loss

of steam pressure from behind the steam pistons as the

piston assemblies move through the cylinders during the

power stroke. The connector and the strip guide are

bolted to the top of the barrel (fig. 4-6). The connector

lifts the sealing strip off its seat to permit passage of

the shuttle assembly along the cylinder. The strip guide

returns the sealing strip to its seat after the connector

passes under it, minimizing loss of steam pressure as

the piston assembly advances through the power stroke.

In addition (see figs. 4-6 and 4-10), the connector has

interlocking “dogs,” which couple with matching

“dogs” on the shuttle assembly to effect the connection

between the connectors and the shuttle assembly.

The tapered spear and bronze piston guide are

bolted to the forward end of the barrel. The piston

guide acts as a bearing surface for the piston assembly

and keeps it centered with respect to the cylinder walls.

The tapered spear works in conjunction with the

water-brake cylinder assemblies to stop the piston

assemblies and shuttle at the end of the power stroke.

Shuttle

The shuttle (fig. 4-10) carries the forward motion of

the pistons to the aircraft by means of a launch bar

attached to the aircraft nose gear and connected to the

nose gear launch shuttle spreader. The shuttle and the

piston assemblies are connected by the meshing of

interlocking “dogs” of the piston assembly connectors

and the shuttle frame (fig. 4-10).

The shuttle is essentially a frame mounted on

rollers. Two pairs of rollers fitted with roller bearings

are installed on hubs mounted at each end of the shuttle

frame. The shuttle is installed in a track between and

above the launching engine cylinders. The trough

covers form the shuttle track, which supports and

guides the shuttle.

The bearings of the rollers are lubricated through

fittings, which are accessible through the slot in the

shuttle track. The shuttle blade is part of the shuttle

frame and is the only part that protrudes above the

4-9