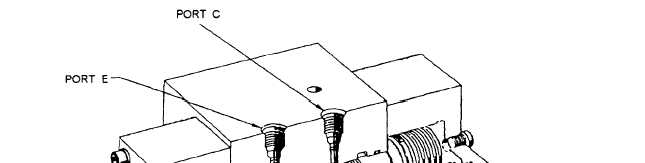

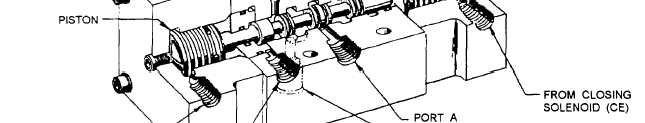

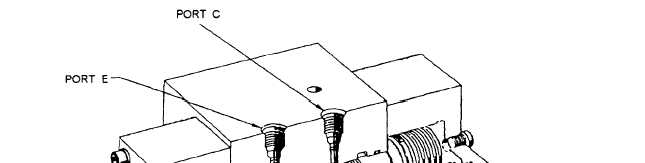

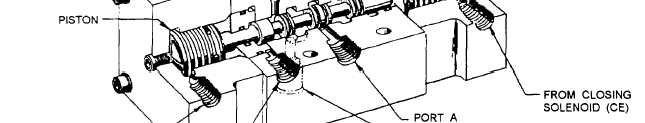

Figure 4-33.—Exhaust-vaIve hydraulic lock valve.

valve is locked in this position by pressure from port A

LINEAR AND ROTARY RETRACTION

acting on the larger working area of the lock valve

piston.

STEAM CUTOFF PRESSURE-SWITCH

INSTALLATION

The steam cutoff pressure-switch installation (fig.

4-34) is located at a point in the catapult power stroke

determined during the catapult certification program.

Flexible tubing connects the steam cutoff pressure

switch assembly to a port in one of the launching

cylinders. During a launch, the pistons pass the port,

allowing

steam to flow into the steam cutoff

pressure-switch installation and energize the LAUNCH

COMPLETE relays. These relays initiate closing of the

launch valves, opening of the exhaust valve, and the

subsequent automatic advancing of the grab. The steam

cutoff pressure-switch installation must de-energize the

LAUNCH COMPLETE relays before the catapult can

complete the interlock circuit for the next launch cycle.

The steam cutoff pressure-switch assembly is housed in

an intrusion-proof enclosure outside the trough. The

steam cutoff pressure-switch assembly contains two

pressure switches, a disk orifice, and a steam manifold,

which directs steam pressure from the flex hose to the

switches. The switches are nonadjustable, and the

contacts close at approximately 20 psi and open at

approximately 10 psi.

SYSTEMS

The function of both the linear and the rotary

retraction engines is to hydraulically control the

movement of the grab and to maneuver the shuttle

forward and aft when slow movement is required.

Normally, the engines are located directly below the

flight deck in close proximity to the launching engine

so excessive cable reeving and hydraulic lines and

piping are not required.

LINEAR RETRACTION ENGINE

Essentially, this system consists of the retraction

engine

cylinder and piston; the main hydraulic

accumulator; air flasks; the grab; the cables, which

couple the grab to the retraction engine; the crosshead

sheaves; cable equalizers; associated valves; and

electrical controls and piping. The general arrangement

of a linear retraction engine is shown in figure 4-35.

DRIVE SYSTEM

As shown in figure 4-36, the linear retraction

engine drive system consists of a grab, two advance

cables, two retrieving cables, an advance cable

equalizer, a retrieving cable equalizer, a crosshead, and

the various sheaves. The drive system operates in

conjunction with the retraction engine and the hydraulic

4-26