exhaust valve from opening until the launching valve is

closed and the keeper valve piston is shifted.

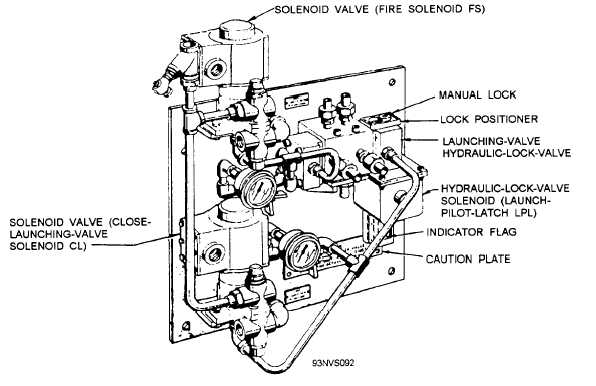

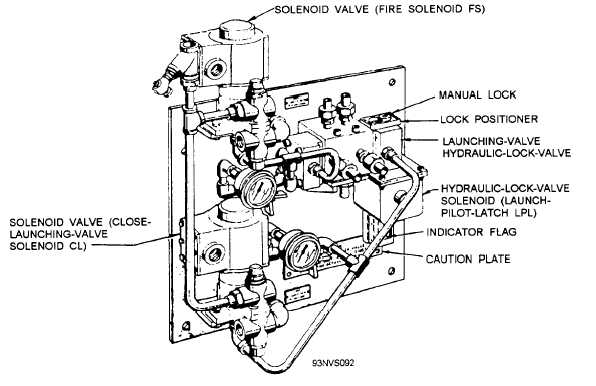

HYDRAULIC-LOCK-VALVE PANELS

There are two hydraulic-lock-valve panels, one for

the launching valves (fig. 4-30) and one for the exhaust

valve (fig. 4-3 1). The launching-valve hydraulic-lock-

valve panel consists of two air-solenoid valves, the

hydraulic lock valve, the launch pilot latch solenoid,

and piping connections. The launching-valve hydraulic

lock valve (fig. 4-32) provides a hydraulic lock to hold

the launching-valve control valve in the FIRED position

until launching is completed or until the launching-

valve emergency cutout valve is placed in the EMER-

GENCY position, by controlling the flow of fluid to the

launching-valve control valve.

The launch pilot latch solenoid controls a plunger

that prevents the lock valve from being shifted to the

FIRED position unless the catapult control system is in

the FINAL READY phase of operation. (A manual lock

screw [fig. 4-32] is provided to secure the valve during

nonoperational periods.) When the catapult FIRE circuit

is energized, the fire air-solenoid valve directs air

pressure to shift the lock valve to the fired position.

This causes pressurized fluid to be directed from port A

through port B to the launching-valve control valve, the

keeper valve, and port D via the launching-valve

emergency cutout valve. Fluid pressure in port D

provides a hydraulic lock to prevent the valve from

shifting. When the catapult LAUNCH COMPLETE

circuit is energized, the close launch valve air-solenoid

directs air pressure to again shift the lock valve, venting

port D to gravity and directing pressurized fluid from

port A through port C to the launching-valve control

valve and closing the launching valves. (During a

HANGFIRE condition, port D is vented and port C is

pressurized when the launching-valve emergency cutout

valve is placed in its EMERGENCY position, ensuring

that the launching valves remain closed.)

The exhaust-valve hydraulic-lock-valve panel

consists of the exhaust-valve hydraulic lock valve, two

air-solenoid valves, and piping connections (fig. 4-31).

The exhaust-valve hydraulic lock valve (fig. 4-33)

opens and closes the exhaust valve by controlling the

flow of hydraulic fluid to the exhaust-valve actuator.

When the exhaust-valve open solenoid is energized, air

pressure is directed to the opening side of the lock

valve, causing it to shift. This allows fluid to flow from

port A, out port B, through the keeper valve, and into

the opening chamber of the actuator. Fluid also flows

from port D to lock the valve in the OPEN position.

When the exhaust-valve closed solenoid is energized,

air pressure shifts the lock valve to the closed position,

allowing fluid to flow from port A, out port C, and into

the closing chamber of the exhaust-valve actuator. The

Figure 4-30.—Launching-valve hydraulic-lock-valve panel.

4-24