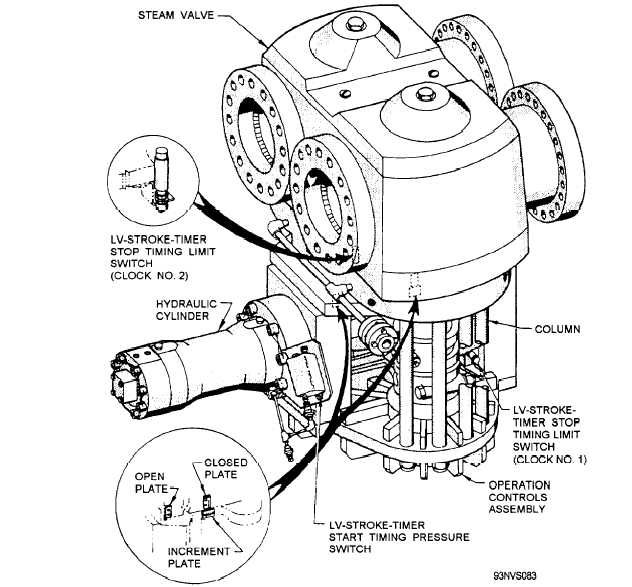

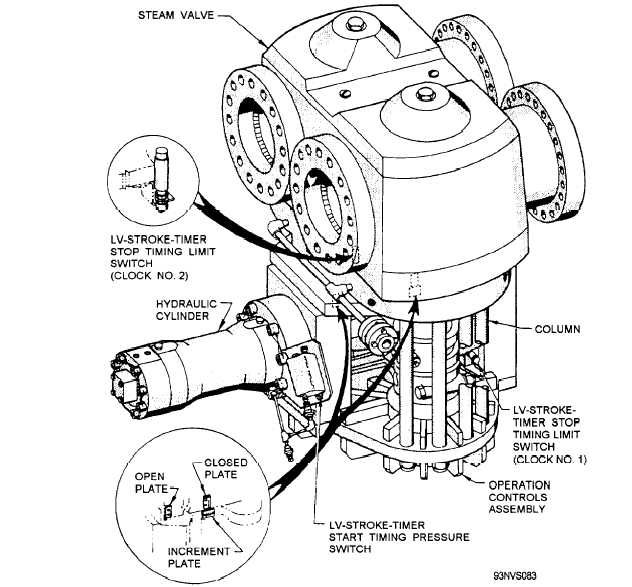

Figure 4-21.—Launching valve assembly (rotary).

movement needed for opening and closing the steam

valve. Vertical movement of the plugs is obtained by

the action of the lift nuts. Each lift nut has a steep angle

thread that mates on each steam valve plug shaft. Each

lift nut is connected to the crosshead by a lifter lever

and a lifter link. Movement of the crosshead, which is

connected to the hydraulic cylinder piston rod, causes

the lift nuts to rotate and the plugs to move toward or

away from the steam valve body seats. Rotational

movement of the plugs is also obtained by movement

of the crosshead. Each plug shaft is connected to the

crosshead by a rotator lever and a rotator link. With the

steam valve in the CLOSED position, the plugs are

fully seated. When the crosshead starts to move to the

OPEN position, the lift nuts move the plugs downward,

and the links and levers begin to rotate. Due to the

geometrical arrangement of the levers, the plugs are

moved away from the body seats before rotation begins.

As the crosshead stroke approaches the FULL OPEN

position, the plugs move toward the valve body seats.

When the valve is fully opened, the plugs are not in

contact with the body seats, because of the unequal

lengths of the links, and the plugs and body parts are in

perfect alinement. As the crosshead moves to the

CLOSED position, the links and levers rotate the plugs

upward to seat the plugs against the seats.

Variations in the launching valve stroke rates may

seriously affect catapult performance. The launching

valve stroke timers provide a means of detecting

differences in the launching valve stroke. Switches

located on the launching valve assembly (fig. 4-21) are

4-19