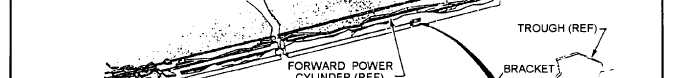

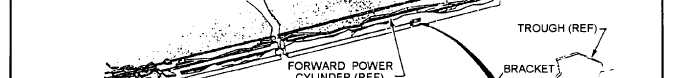

Figure 4-16.-Clinder elongation indicator installation

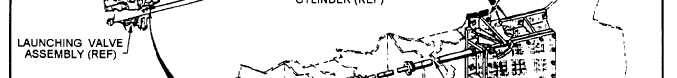

and upper and lower cover support bars (see fig. 4-17).

The trough is of welded construction, made of steel

plates, and is reinforced on the outside. The troughs are

built with voids outside the trough walls. The bolted

down access plates for these voids form the flight deck

at both sides of the bow catapults. The access to the

voids on waist catapults is from below deck through the

sides of the voids. The trough contains heaters used to

preheat the catapult and to maintain minimum catapult

operating temperature during all weather conditions.

The launching engine cylinders rest on lubricated

bearing pads mounted in the trough. The only points at

which the launching engine is secured to the ship

structure are at the thrust unit at the aft end of the

launching engine and at the forward or buttress plate

end of the water-brake cylinders. The forwardmost

launching engine cylinders telescope over the

water-brake cylinders.

This allows longitudinal

expansion and contraction during catapult heating and

cooling.

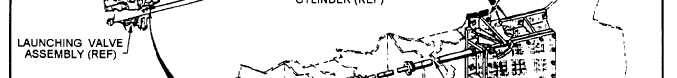

Catapult Trough Covers

The trough covers perform a dual function. They

cover the catapult trough which accommodates the

launching cylinders, and they form a shuttle track,

which supports and guides the shuttle and grab during

catapult operation (fig. 4-17). All covers are designed

to withstand a vertical rolling shuttle load of 264,000

pounds total (132,000 pounds to each cover) in upward

directional force and 100,000 pounds wheel-load in

downward directional force. The standard trough covers

are

made in

various lengths: the 6-foot-long

intermediate and aft covers, the 4-foot forward cover

4-15