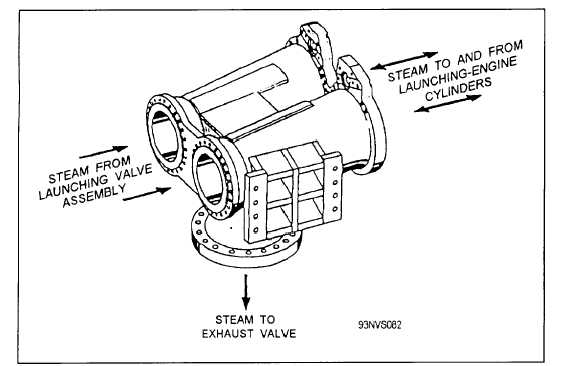

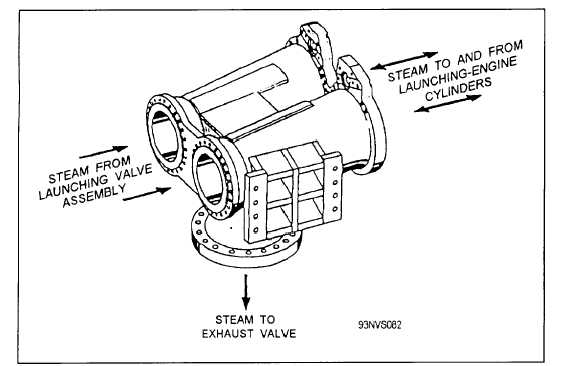

Figure 4-20.—Thrust exhaust unit.

prevents aft expansion of the launching engine

cylinders.

The thrust exhaust unit connects the

launching valves and the exhaust valve to the launching

engine cylinders.

Launching Valve Assembly

The launching valve assembly (fig. 4-21) consists

mainly of a steam valve assembly, a hydraulic cylinder

assembly, an operation control assembly, and the

launching valve stroke timer electrical installation. A

closed plate and an open plate are located on the

operation controls frame and an increment plate is

located on the operation controls crosshead. The

position of the valve can be determined by the

relationship of the increment plate to the closed and

open plates.

Steam Valve

The steam valve (fig. 4-22) admits and shuts off the

flow of steam to the launching engine cylinders during

catapult operations. With the valve in the CLOSED

position, two plugs in the valve are in full contact with

the valve body seats, providing a tight seal. When the

valve is opened, the plugs are moved away from the

valve body seats and rotated 90°. In the OPEN position,

the circular openings in the plugs are in line with the

valve body passages.

Hydraulic Cylinder Assembly

The hydraulic cylinder assembly is connected to the

operation control assembly (fig. 4-23). The cylinder

assembly is actuated by pressurized hydraulic fluid to

open and close the steam valve assembly. When

pressurized fluid is applied to port E, the piston moves

to the opposite end of the cylinder to open the steam

valve. The rate of movement of the piston is faster at

the beginning of the stroke, because of the effect of the

metering rod. At the beginning of the opening stroke,

fluid flows out of port A and port B. When the piston

has moved approximately 1 inch into the cylinder, the

metering rod shuts off the flow of fluid from within the

cylinder to port B. At the end of the opening stroke, the

orifice snubber controls the escape of fluid from the

cylinder. When pressurized fluid is applied to port A,

the piston moves toward the opposite end of the

cylinder to close the steam valve. At the end of the

closing stroke, the tapered end of the piston rod enters

the flange. This prevents the moving parts from

slamming to a stop and possibly being damaged.

Operation Controls Assembly

The operation controls assembly is attached to the

bottom of the steam valve assembly (fig. 4-24). The

assembly provides vertical movement needed for seating

and unseating the steam valve plugs and rotational

4-18