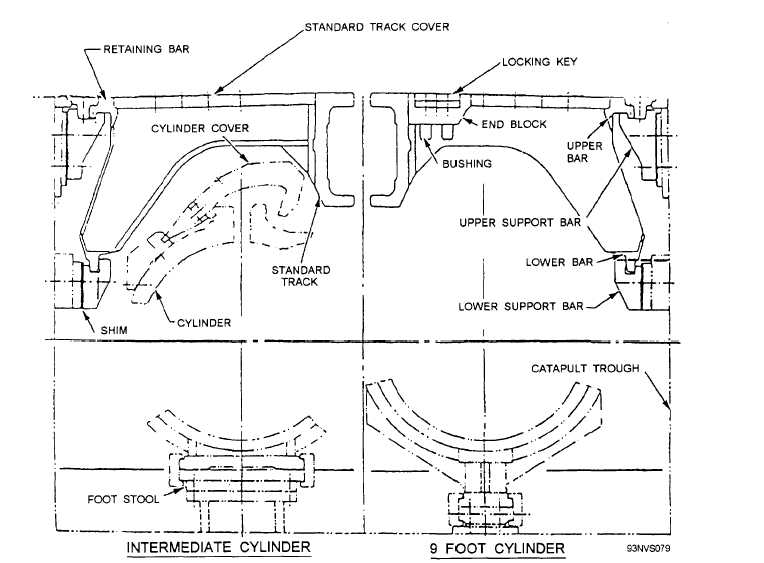

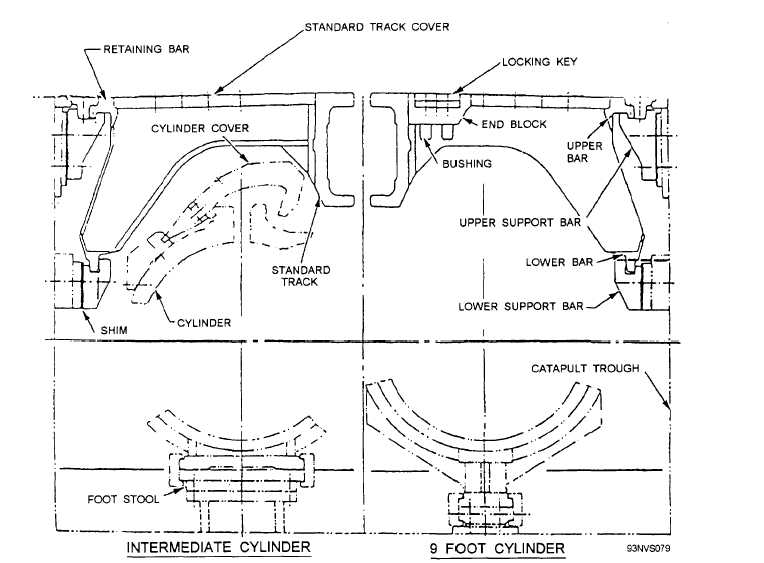

Figure 4-17.—Typical catapult trough cross section.

and the 8-foot to 10-foot-long forward covers (see

fig. 4-18). The 6-foot-long aft trough cover incorporates

a removable access plate to facilitate maintenance

procedures. The forward pair of trough covers is

provided with a 53-inch-long splash bar, which is

inserted in the slots of the upper track flange of these

covers. The trough covers are supported by the upper

and lower support bars, which are mounted on the

trough side walls. Each cover is individually keyed to

the upper support bars. The locking keys assure smooth

shuttle load transition between covers and restrain the

UP and DOWN movement between the cover ends. The

trough covers are held in place with retaining bars.

STEAM SYSTEM

The catapult steam system (fig. 4-19) consists of the

steam fill valves, dry-steam receivers or wet-steam

accumulator, the launching valves, the exhaust valve,

the pressure-breaking orifice elbow, and the steam

manifold. Associated with the steam system are the

capacity selector valve, launching valve-control valve,

exhaust valve keeper valve, launch complete steam

pressure cutoff switch installation, and the external

steam preheating system.

The steam fill valves control the flow of steam from

the ship’s boilers to the dry-steam receiver or wet-steam

accumulator. A steam blowdown valve is used to reduce

excess steam pressure or completely blow off steam

pressure when required. All steam fill and blowdown

functions are controlled from the catapult main control

station.

The thrust exhaust unit (figs. 4-19 and 4-20)

anchors the aft end of the launching engine and

4-16