CHANGE OF PRODUCT IN

AIRCRAFT REFUELERS

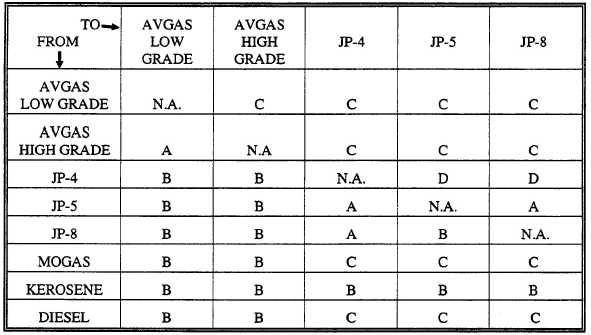

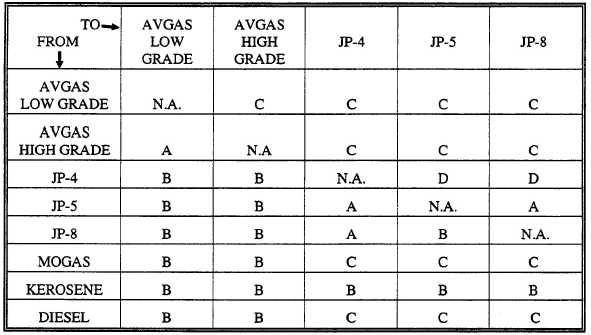

Change of product in mobile refuelers is

performed according to table 7-2. Product used to

flush tanks and piping MUST be treated as

contaminated fuel. Samples must be visually

inspected for sediment and water, and the specific

gravity of each must check within 0.5 of the corrected

API of the appropriate product in storage.

Change of Product in

Storage Tanks

The Naval Petroleum Office must be contacted

concerning instructions for the change of product

grade in storage tanks.

ASHORE AVIATION FUELS SAFETY

LEARNING OBJECTIVE: Describe the safety

requirements and procedures that must be

followed during fueling operations ashore.

This section contains safety procedures and re-

quirements that either are general in nature and

therefore not covered in other chapters of this

manual or are extremely important and repeated

here for emphasis. Any departure from the

procedures of this section may adversely affect the

overall safety of the operation being performed.

Although the procedures and requirements con-

tained in this manual are as complete as possible,

they are no substitute for experience and a thorough

knowledge of aviation fuels and their inherent

Table 7-2.—Change of Grade Procedures for Aircraft Refuelers

LEGEND:

A. Drain, fill with desired product.

B. Drain, flush 300 gallons (600 gallons if total filter/separator capacity is 600 gpm) of desired product,

drain, fill with desired product. recirculate, sample and test. Pay particular attention to sumps,

pumps, filters, hoses and other components likely to trap quantities of liquid.

C. Drain, steam clean, and dry. Remove fuel from all refueling system components—that is, sumps,

pumps. filters, hoses, and piping—prior to initiating steam cleaning. Replace the filter separator and

monitor elements.

D. Drain, gas-free, and fill with desired product.

7-28