In some cases, aircraft must be defueled and then

refueled before flight operations can proceed.

When a fuel is found to be contaminated, the

contaminant must be tracked back to its source and

the cause corrected. Until the cause of the

contamination

is

found

and

corrected,

the

contaminated system cannot be used. The fuel system

may be a mobile refueler, air station hydrant

refueling system, or the entire fuels system of an

aircraft carrier. Contaminated fuel may affect the

operation of one aircraft or the operation of an entire

air wing. For these reasons, be careful in every phase

of fuel handling to prevent contaminants from

entering the fuel.

CAUSES OF FUEL CONTAMINATION

How can you find out the causes of fuel

contamination? How can you find out how much

contamination is too much? Before you can determine

amounts of contamination, you have to be able to

understand the units of measurement used to identify

contamination. The two major units for measuring

the size of contaminants are microns for solids and

parts per million (ppm) for water.

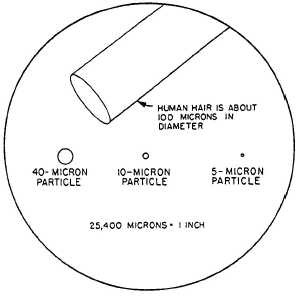

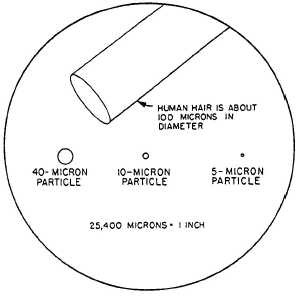

There are approximately 25,400 microns in 1

inch. Figure 3-1 gives you 2 microscopic view of a

human hair, which is about 100 microns in diameter,

and compares it with a 5-micron contaminant.

Parts per million is the reference used for water

contamination. If you take a 32-oz sample bottle and

fill it 3 1/4 inches from the bottom, the amount you

will have is about 500 milliliters (ml). Break that 500

ml down into one million little pieces. You now have 1

ppm.

As you now realize, the equipment used in the

quality surveillance laboratory has to be very

accurate to make measurements that small.

Operation of the lab equipment will be covered later

in this chapter.

HUMAN FACTOR

Equipment now in use can remove most of the

contamination that may be present in a fuel. It

cannot separate two mixed or blended fuels. It cannot

effectively reduce the contamination below the

required limits if the contaminant level is too high.

YOU must be careful to prevent the introduction of

contamination in all phases of fuel handling.

Additionally, all steps of contamination removal

MUST be properly performed.

Inspection and sampling procedures are the only

means to ensure that the equipment is performing

properly. Unless the equipment is properly operated

and the sampling procedures are carefully followed,

the problem will always remain. Thus, the most

important factor in preventing and removing

contamination in fuels is the awareness of the people

who handle the fuel.

Figure 3-1.—Enlargement of small particles and

comparison to a human hair.

The equipment is only a machine. You, the ABF,

the educated operator, make a quality surveillance

program work.

LIMITS OF CONTAMINATION

To be acceptable for delivery to aircraft, jet fuels

must be clean and bright. They must not contain

more than 5 ppm free water or 2 mg/liter particulate

contamination. The terms clean and bright have no

relation to the natural color of the fuel. Jet fuels are

not dyed and they vary from clear, water-white to

straw-yellow colored. Clean means the absence of any

cloud, emulsion, visible sediment, or free water.

Bright, means the fuel has a shiny, sparkling

appearance.

A cloud, haze, specks of particulate matter, or

entrained water indicate that the fuel is unsuitable

and point to a probable breakdown in fuel handling

equipment or procedures. If contamination limits are

exceeded, delivery of fuel to aircraft shall be stopped

and corrective measures completed before resuming

fueling operations.

CAUSES OF CONTAMINATION

Steps should be taken to find the source of

trouble and corrective measures taken immediately.

See figure 3-2 for the various types of contamination

that may be detected visually. The first sample of fuel

in this illustration is an acceptable fuel.

Water

Water in fuels may be either fresh or salt and

may be present either as dissolved or free water.

Dissolved

3-6