purifier. The bowl casing drain line directs drained

liquid into the sump tank. A short length of rubber

hose is installed in this line to perform the same

function as the flexible pipe connection in the water-

discharge line.

Drive Housing and Assemblies

The drive housing bolts to and supports the bowl

casing, cover, and bowl shell assembly. The drive

housing contains the spindle assembly, direct drive

assembly, speed counter, brake, and lubrication

system.

The spindle assembly (fig. 4-29) is the vertical

drive shaft for the bowl shell assembly. Three sets of

ball bearings support the spindle assembly; a set at

the top, a set at the center, and a set at the bottom.

All three sets of ball bearings are lubricated by oil.

Located between the upper and lower bearings of the

center set of ball bearings is a large vertical spring.

This spring acts as a shock absorber to absorb any

vertical thrust of the spindle’s shaft when the purifier

is started. Six equally spaced horizontal springs

surround the upper set of ball bearings. These

springs absorb and cushion any horizontal movement

of the bowl shell assembly and thus reduce vibration.

The lower end of the spindle’s shaft is geared to the

horizontal drive shaft of the direct drive assembly.

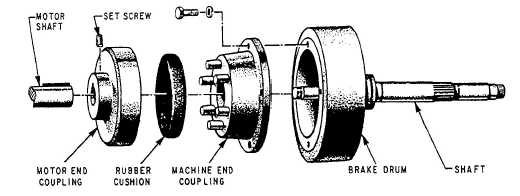

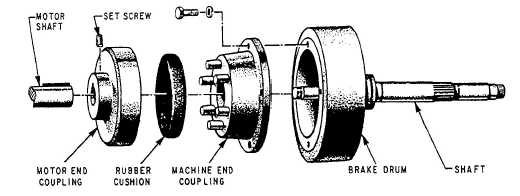

The direct drive assembly transmits drive motor

power to the spindle, which, in turn, transmits power

to the bowl shell assembly. The direct drive assembly

(fig. 4-30) connects the purifier to the motor shaft by

a flexible coupling. The coupling consists of two

coupling halves, with the motor end fitted to the

motor shaft and the purifier end fastened to the

brake drum with four bolts. Each coupling half has

protruding studs (which are offset of each other) that

engage a rubber cushion installed between the two

coupling halves.

The drive motor shaft turns the coupling, which

turns horizontal drive shaft. The horizontal drive

shaft is supported by two ball bearings; an outer and

an inner bearing. The outer and inner shaft bearings

are lubricated by oil. A worm wheel gear is keyed to

the drive shaft. This gear engages the gear at the

base of the spindle assembly. A smaller gear, which is

part of the worm wheel gear, is used to drive a speed

counter.

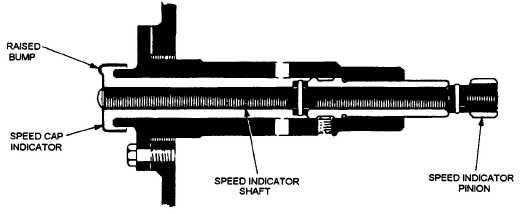

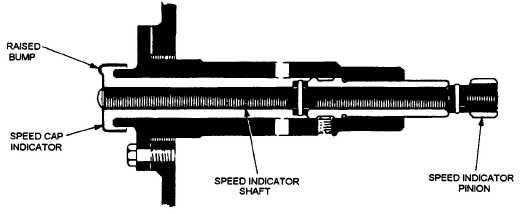

The speed counter (fig. 4-31) is used to determine

the rpm of the bowl shell assembly. Basically, it

consists of a shaft that penetrates the drive housing.

One end is

Figure 4-30.—Direct drive assembly.

Figure 4-31.—Speed counter.

4-37