inside the drive housing and the other end is outside.

The inside end is geared to the worm wheel gear;

therefore, when the direct drive assembly rotates, the

speed counter shaft rotates. The speed counter, but,

rotates at a much slower rate because of the gear

ratio. The outside end of the speed counter shaft is

covered by an attached cap. The cap has a raised

bump on one side of its top. Bowl speed is determined

by the operator who places his finger on the outer

edge of the cap and then counts the number of times

the raised bump touches his finger in 1 minute.

During full bowl rpm, the count should be between

146 and 150 times per minute.

Because of the gear ratio, the drive motor rotates

at 1,770 rpm, the bowl rotates at 4,100 rpm, and the

speed counter rotates at 146 to 150 rpm. A handbrake

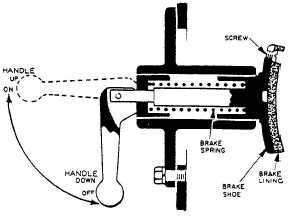

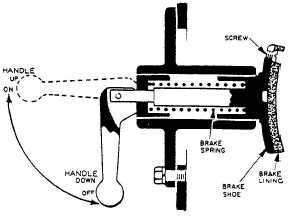

(fig. 4-32) is provided to stop the purifier. This brake

is for emergency use only. It consists of a spring-

loaded brakeshoe and an eccentric handle. The

brakeshoe has a replaceable section of bonded brake

lining. When the handle is down, the brake is off.

When the handle is raised to the up position, the

brake is on. In the on position, the spring forces the

brakeshoe and lining against the outer surface of the

brake drum. Friction, thus created, causes the

purifier to come to a stop.

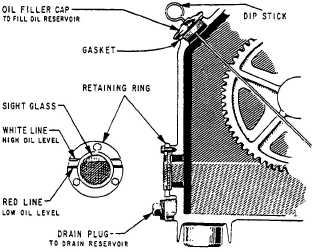

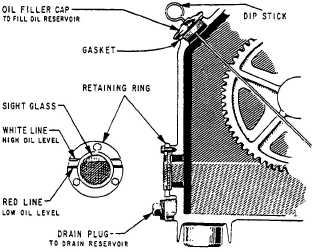

In the base of the drive housing is an oil sump

for the oil lubrication system (fig. 4-33). All the

bearings on the spindle and drive shaft are lubricated

by this oil. The drive housing is divided into two

compartments. One of these compartments contains

the direct drive assembly coupling and the other

contains the gears and bearings that are lubricated

by oil. A metal partition separates the two

compartments. The direct drive shaft passes through

this partition and a gasket is installed around the

shaft to prevent oil from entering the direct drive

coupling compartment. The worm wheel gear on the

drive shaft is partially submerged in the oil. Rotation

of this gear splashes the oil about within the oil

Figure 4-32.—Brake assembly.

Figure 4-33.—Oil lubrication system.

lubrication compartment, thus supplying oil to the

bearings and gears. The oil sump holds from 8 to 8

1/2 quarts of grade 90 gear oil. Proper oil level is

determined by a circular sight glass on the side of the

drive housing. The glass retaining ring has two

inscribed lines to indicate proper oil level. The white,

top line, is the high or full oil level. The red, bottom

line, is the low oil level mark.

On some installations where the oil sight glass

could not be seen easily in its normal position, the

sight glass has been extended out and turned to give

a clear view to the operator, or a dip stick has been

added to the oil filler cap. The dip stick has two

marks. The lower mark indicates lubricating oil

should be added. Fill to the upper mark. To check the

oil level, pull the stick completely out through the

cap. Wipe with a clean, dry rag. Push the stick all the

way in through the cap and pull it out again to read.

Be sure the stick always rests on the cap.

An oil fill cap is located near the top of the drive

housing. An oil drain plug is at the base of the oil

sump.

Bowl Shell Assembly

The bowl shell assembly (fig. 4-34) provides the

working area for separation of contaminants from JP-

5. The entire bowl shell assembly sits on top of the

spindle assembly. The spindle assembly causes the

bowl shell assembly to rotate. This rotation is

transmitted to the fuel, thus providing the necessary

centrifugal force to cause separation to take place.

During operation, the bowl shell assembly contains a

fresh water seal to prevent loss of the JP-5. Most of

the separated solids and emulsions are retained

within the bowl shell assembly, but are completely

removed from the line of flow of the liquids.

4-38