b. Work the wire helix (spiral) down and off

the coupling end.

c. Remove the coupling end.

d. Remove the wire helix.

3. Make sure the hose is squared up, and mark the

hose for cutting, using the taper sleeve as a guide.

After marking, remove the taper sleeve.

4. Cut fabric-reinforced hose with a sharp knife

wetted with fresh water. Cut wire-reinforced hose with

a new or sharp hacksaw with fine teeth. Insert a round

wood plug into the hose to eliminate the danger of

loosening the inner liner or damaging the wire rein-

forcement while cutting.

coat of barrier.

5. Paint the freshly cut hose end lip with a light

coat of zinc chromate primer to provide a moisture

barrier.

6. Slide the external taper sleeve back on the hose.

7. Slide the wire helix on and position it about 6

inches down from the end of the hose.

8. Insert the coupling end into the hose, ensuring

the hose is bottomed at the lip of the coupling end.

9. Work the wire helix up and into position over

the inserted part of the coupling end. Be careful not to

overexpand the wire helix.

10. Slide the taper sleeve into position and screw it

tightly to the coupling end.

11. Hydrostatically test the hose as instructed in

the appropriate MRC.

12. Cut the continuity wire 10 to 12 inches longer

than the hose, to compensate for hose stretch.

13. Reinstall the continuity wire and spiders.

Check for electrical contact between the contact

buttons at the hose ends, using an ohmmeter.

Maximum allow-able reading is 40 ohm.

14. Upon reinstallation on a station, flush the hose

until an acceptable sample is obtained.

QUICK-DISCONNECT

COUPLING (QDC)

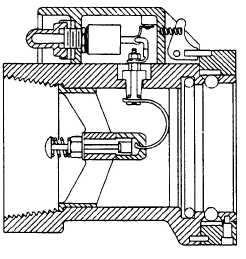

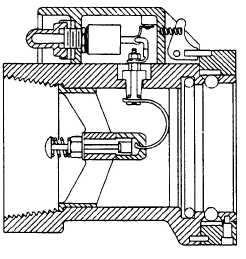

The quick-disconnect coupling (fig. 5-14) is de-

signed to provide the means of attaching the fuel

nozzle to the hose. It also contains the switch to

energize or de-energize the SOPV. When operating the

quick-disconnect coupling, don’t jam the switch, and

don’t drop the coupling on the deck.

The quick-disconnect coupling has a female thread

on one side to fit the male threads of the hose. The

other end has a female ball bearing quick-release that

receives the male end of the nozzle adapter.

NOZZLE ADAPTER

The flange side of the nozzle adapter is bolted to

the nozzle. The male end opening provides a means of

installing a 100-mesh strainer inside the nozzle as-

sembly. The strainer is held in place by a snap ring

that fits into a recessed groove inside the male end.

PRESSURE FUELING

NOZZLE

The pressure fueling nozzle connects to all NATO

military aircraft and is designed to provide a leak-proof

seal between the nozzle and the aircraft for high-

capacity fueling operations. This includes sup-plying

fuel under pressure to aircraft, and removing fuel by

suction from aircraft.

The pressure fueling nozzle is attached to the hose

by the nozzle adapter and quick-disconnect coupling.

The nozzle outlet attaches solidly to the aircraft refu-

eling adapter. The nozzle is secured to the aircraft by

aligning the slots in the nozzle with the lugs on the

aircraft adapter, pressing the nozzle firmly against the

aircraft adapter, and rotating the collar clockwise until

the internal stops are contacted.

The JC Carter D-1 and MD-1 are the pressure

fueling nozzles most widely used in the Navy.

Figure 5-14.—Quick disconnect coupling with

toggle switch.

5-13