is to insert the defueling suction hose into the tank

through the tank fill opening. For total defueling,

defuel through the aircraft pressure fueling adapter.

The discharge hose from the defueling unit is

connected to the fill connection through a special

fitting.

CONTINUITY

Electrical continuity is a firm requirement for all

aircraft refueling stations. Electrical continuity must

be present and maintained to ensure personnel

safety, equipment protection, and efficient fueling

operations.

With electrical continuity present, the nozzleman

fueling the aircraft has immediate control of fuel

flow. This is essential to prevent fuel spills and

possible accidents during aircraft refueling. Electrical

continuity is present when wires are provided and

switches are set to allow an electrical current to flow

away from the controller and back to it through a

solid metallic path.

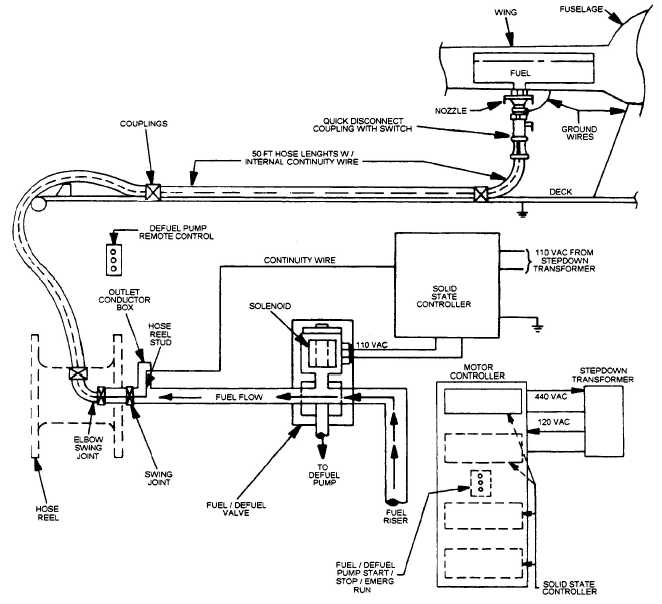

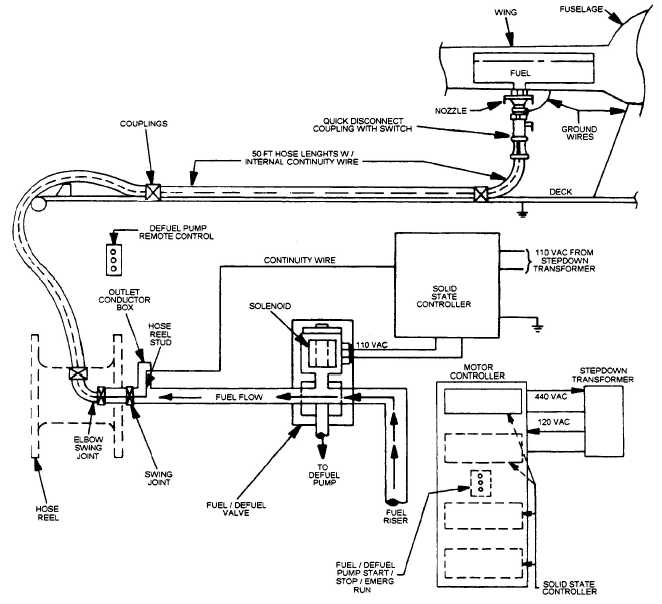

Now, let’s follow the continuity circuit (fig. 5-17).

Starting the defuel pump applies power to the solid

state relay, but nothing happens, because the circuit

is broken. Make sure your ground wire to the deck is

grounded to metal. Then hook it to the aircraft.

Remove the dust cover and connect the nozzle. Flip

the switch in the quick-disconnect housing to ON,

which closes the circuit. The ground then goes back

through the spiders in the quick-disconnect coupling

to the wire in the hose. From there, it goes back to

the

Figure 5-17.—Electrical continuity control for the Cla-Val fueling station.

5-16