the burners in the quantity and at the pressures

required. A secondary function is to supply

compressor bleed air for various purposes in

the engine and aircraft. The compressor provides

space for mounting accessories and engine

parts.

There are two basic types of compressors. The

compressor type is also the engine type, so a

centrifugal-flow compressor is in a centrifugal

engine. Centrifugal-flow compressors have a

compression ratio of 5:1. Present-day axial-

flow compressors have compression ratios

approaching 15:1 and airflows up to 350 lb.

The addition of a fan raises these values to 25:1

and 1,000 lb/sec.

Centrifugal-Flow Compressors

The single entry centrifugal-flow compressor

(fig. 1-15) consists of an impeller (rotor element),

a diffuser (stator element), and a manifold. The

impeller picks up and accelerates air outward to

the diffuser. The diffuser directs air into the

manifold. The manifold distributes air into the

combustion section. Double entry centrifugal-flow

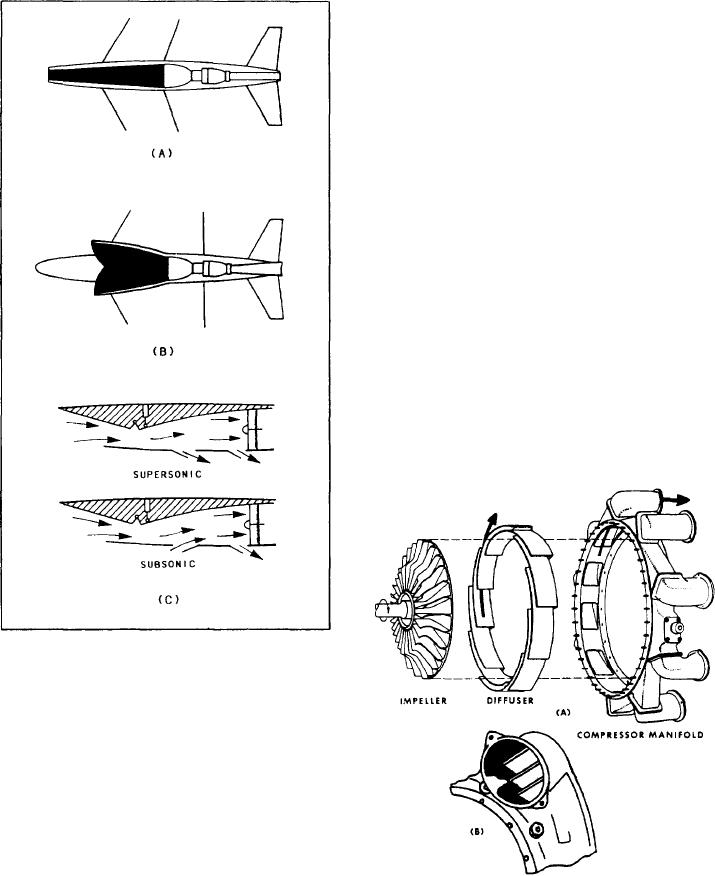

Figure 1-14.-Air entrance designs. (A) Single entrance;

(B) dual entrance; (C) variable entrance.

is to vary the area, or geometry, of the intake

duct. Navy aircraft use this method, incorporating

movable ramps as shown in figure 1-14, view C,

to change the area and shape of the intake

duct.

COMPRESSOR SECTION

The primary function of the compressor

is to supply air in enough quantity to satisfy

the requirements of the combustion burners.

Figure 1-15.-(A) Elements of the centrifugal compressor;

Specifically, the compressor increases the air mass

(B) air outlet elbow with turning vanes for reducing air

pressure losses.

received from the air inlet duct and directs it to

1-13