pounds passing to the engine is subtracted

from the original reading. Thus, the fuel counter

continually shows the total quantity of fuel (in

pounds) remaining in the aircraft. However, there

are certain conditions that cause the fuel counter

indication to be inaccurate. Any fuel remaining

in the droppable tanks when they are jettisoned

is indicated on the fuel counter as fuel still

available for use. Any fuel that leaks from a tank

or a fuel line upstream of the flowmeter is not

counted. Any fuel supplied to the engine by the

emergency pump is not counted.

Some continuous-flow fuel systems have a fuel

quantity gauge for each tank or group of inter-

connected tanks. If the system has a main tank

with auxiliary tanks feeding into it, a fuel quantity

gauge is normally for the main tank. In this type

of system, the pilot relies on the indication of the

fuel counter (flowmeter). All fuel in the auxiliary

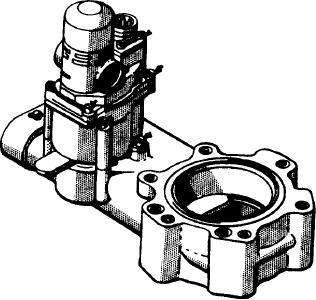

Figure 4-10.-Motor-operated shutoff valve (gate valve).

tanks is transferred to the main tank and fed to

the engine. When all fuel except that in the main

tank has been consumed, the fuel quantity gauge

Fuel Level Control Valves.-- Fuel level

provides a more reliable indication of the fuel still

control valves control fuel levels in a tank during

available. The accuracy of its indication is not

ground fueling or fuel transfer to the main tank.

affected by the conditions listed in the preceding

There is one fuel level control valve for each tank,

paragraph; that is, leakage and emergency system

auxiliary tank, or group of interconnected tanks.

supply.

When used for fuel transfer, the valves are located

The fuel quantity gauge normally used in air-

at different levels in the main tank. Fuel is then

craft is an electronic (capacitor) type for measur-

transferred from the auxiliary tanks in the order

ing fuel in aircraft in pounds. Normally, the

designed by the manufacturer. During normal

capacitor-type fuel gauge is used without a

operation of the fuel system, the boost pumps for

flowmeter, although most engines have provisions

all the tanks are turned on before the engine is

for installing one if it is required,

started. Each auxiliary tank boost pump continues

A low-level switch is incorporated in the fuel-

to operate until the tank is emptied; then the fuel

level transmitter. This switch turns on an indicator

pressure warning light comes on and the boost

light in the cockpit when the fuel in the tank drops

pump is turned off by the pilot. Thus, fuel is

to a specific low level. This signal informs the pilot

delivered under boost pump pressure to each fuel

that the fuel supply is almost exhausted.

level control valve. The fuel then remains in the

tank or group of tanks to which it is connected.

AIRCRAFT FUEL VALVES.-- Valves are

In the sectional views of the valve in

used to regulate and control the flow of fuel in

figure 4-11, note how the float rises and lowers

the airframe and engine fuel systems. Some of

with the fuel level. When the fuel level in the main

these valves are discussed in the following

tank is high, the float is raised. This closes the

paragraphs.

pilot valve and lifts the ball check from its seat.

Fuel, under boost pump pressure, then passes

through the main valve stem into the valve body.

Shutoff Valves.-- Shutoff valves are two-

Note how the fuel pressure exerted against the

position (open and closed) valves. The manually

operated type is installed to shut off the fuel while

bottom surface of the synthetic rubber diaphragm

holds the main valve closed. This prevents fuel

a unit in the system is being removed or replaced.

Electrically operated shutoff valves control flow

from entering the main tank from the transfer

line.

during fuel transfer and when fuel is being by-

When the fuel level in the main tank drops,

passed because of a defective or damaged unit.

the float moves downward. Note in figure 4-11

Figure 4-10 shows a motor-operated shutoff valve,

how this action allows the ball check to seat in

commonly referred to as a gate valve.

4-16