Selector Valves.-- In the continuous-flow

identified by the bright wire braid outer cover with

system, selector valves are not used for tank-to-

red markings. These markings are repeated

engine selection during normal operation.

6 inches apart.

However, in many installations there are selector

This hose is designed for aircraft power plant

valves to enable the pilot or mechanic to control

and airframe fuel and oil lines. It is widely used

the fuel flow for special purposes. This includes

in jet engines. It is flexible, lightweight, and has

fuel integrity checks, shutting off fuel to the

t h e ability to withstand high operating

engine, bypassing fuel components to allow

temperatures where maximum fire resistance is a

manual operations in emergency conditions, and

prime consideration. This hose may be used in

cross-feeding fuel to different tanks or engines to

submerged applications.

prevent an unbalanced fuel load.

The fitting on this type of hose uses a lip-seal

FUEL LINES AND FITTINGS.-- The fuel

principle, instead of compression, to effect a fluid

lines between the various tanks and between the

seal. This lip-seal is formed during assembly by

tanks and the engine-driven pump are of the

a sharp knifelike spur, which cuts an annular flap

conventional type. They consist of metal tubing

in the hose inner tube. Fitting retention against

or flexible hose. There are drain cocks at low

blowoff is affected by the cutting action of the

spur. This separates the wire braid, which is then

points in the lines so that any water that collects

at these locations may be drained. A quick-

gripped between the nipple and the socket. These

disconnect fitting is often installed in the main fuel

fittings must be marked with a painted stripe to

line to the engine. This fitting permits quick

detect hose pushout after assembly or proof test.

disconnection of the main fuel line when an engine

change is performed.

Rigid Tubing.-- The majority of rigid tubing

The line connecting the various fuel system

used in naval aircraft is manufactured from

units installed on the engine are made of either

aluminum. However, exposed lines and lines

metal tubing or flexible hose. Since these lines

subject to abrasion or intense heat are made of

and fittings must withstand the high pressures

stainless steel. Therefore, you will be concerned

encountered on the discharge side of the engine-

more with stainless steel lines. Whenever an

driven fuel pump, special types are used.

engine fuel line requires replacement, the normal

procedure is to obtain from supply a preformed

Lightweight

Hose Assemblies.-- The

line with fittings attached. If a line must be

lightweight engine hose assembly is designed for

manufactured locally and installed on an engine

continuous operating temperatures of 40

or component, the original line must be duplicated

to +300F. The inner tube is seamless and is of

as exact as possible.

a specially formulated synthetic compound. The

reinforcement and cover are of stainless steel wire

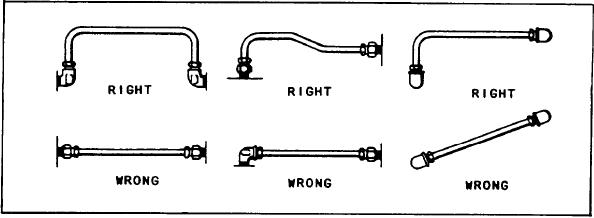

Figures 4-12 and 4-13 show a few of the

braid and consist of a partial inner braid and a

correct and incorrect methods of installing metal

full-coverage outer braid. This hose can be

tubing and flexible hose.

Figure 4-12.-Correct and incorrect methods of installing tubing.

4-18