Auxiliary fuel pumps or booster pumps are

External Fuel Transfer

required in every pressure feed system. They are

needed to supply fuel pressure for starting the

External fuel tank pressurization and transfer

engine and to supply fuel to the primer system.

is accomplished with regulated engine bleed air.

They are also used as an emergency pump in case

An external tank pressure regulator maintains 15

of failure of the engine-driven unit.

to 18 psi air pressure to each of the external tanks.

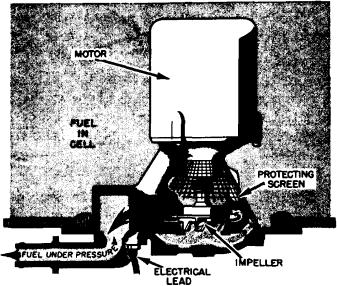

The submerged boost pump is essentially an

Once the tank is pressurized, fuel then transfers

integral unit composed of a centrifugal pump and

through the refuel/transfer shutoff valve into

an electric motor. A screen is provided to protect

the refueling manifold. External fuel is then

the pump from foreign matter. A submerged

transferred to any of the fuel tanks that will

accept the fuel. The refuel/transfer valve will close

boost pump is shown in figure 4-9.

automatically when the external tank is empty.

Strainers.-- Strainers are installed in the tank

The external tank air pressure regulator closes

outlets and frequently in the tank filler necks.

when there is weight on the wheels or when the

These strainers are of fairly coarse mesh and

in-flight refueling probe is extended. This will

prevent the tanks from being pressurized while the

prevent only the larger particles from entering the

fuel system. Other strainers are provided in the

aircraft is on the ground, during an arrested

fuel inlets and in the fuel lines themselves. The

landing, or during in-flight refueling.

latter are fine-mesh strainers.

External Fuel Tank Jettison

FUEL QUANTITY INDICATORS.-- Quan-

The external fuel tanks can be selectively

tity-indicating units will vary. A fuel counter or

indicator, mounted on the instrument panel, is

jettisoned or all jettisoned at one time, such as

electrically connected to a flowmeter installed in

during an emergency situation. The external

the fuel line to the engine. The fuel counter is

tank to pylon fuel/air coupling valves will

s i m i l a r in appearance to an automobile

automatically close the fuel transfer and air

pressurization tubes once the tanks are jettisoned.

speedometer. When the aircraft is serviced with

fuel, the counter is automatically set to the total

number of pounds of fuel in all tanks. As fuel

Fuel Tank Components

passes through the measuring element of the

flowmeter, it sends electrical impulses to the fuel

Common fuel tank parts include pumps,

strainers, fuel quantity indicators, valves to

counter. These impulses actuate the fuel counter

mechanism in such a way that the number of

control fuel level or routing, and vents and drains.

These parts provide capabilities for fueling,

defueling, and fuel system management.

PUMPS.-- The airframe fuel system uses

transfer pumps and boost pumps to deliver a

continuous supply of fuel to the engine(s) under

all operating conditions.

Transfer Pumps.-- Fuel transfer pumps are

installed in the fuel system to pump fuel from the

various tanks of the aircraft to the main or sump

tank. There are several different types of transfer

pumps; common ones are electrically driven or

an ejector-type motive-flow pump. See figure 4-8.

Since the type of pump may differ from one air-

craft model to another, the applicable main-

tenance instruction manual should be consulted

for proper identification and maintenance.

Boost Pumps.-- All Navy fixed-wing aircraft

use pressure feed fuel systems. The basic source

Figure 4-9.-Submerged boost pump.

for this pressure is the engine-driven pump.

4-15