T h e C O2 s t o r a g e tank is designed for

electrically operated starter motor or a com-

maximum working pressure and is equipped with

pressed, air-operated, air turbine starter motor.

a complete Freon (F-12) refrigeration system,

The electric starter motor requires a source of dc

which is automatically controlled by an internally

voltage. The air turbine motor requires a source

mounted pressure switch. The refrigeration system

of compressed air.

maintains a nominal storage tank pressure. The

CO2 System

storage tank is protected by a safety assembly

consisting of a dual switching valve, which, when

The CO2 fire system for the test facility

in the normal position, places in service one

consists of a 2-ton CO2 storage tank, which

auxiliary automatic refrigeration valve, one safety

incorporates a refrigeration system to maintain

valve, and one high-pressure relief disc. The safety

the liquid carbon dioxide at the proper storage

devices provide complete protection against

pressure; a handwheel-operated shutoff valve on

abnormally high tank pressures. An abnormally

the dip tube of the storage tank; pressure-operated

high pressure usually results from power or

control valves for quickly releasing the carbon

compressor failure continuing over a period of

dioxide; a piping system terminating in the CO2

several hours.

discharge nozzles, strategically located in the

protected areas; and various controls, relays,

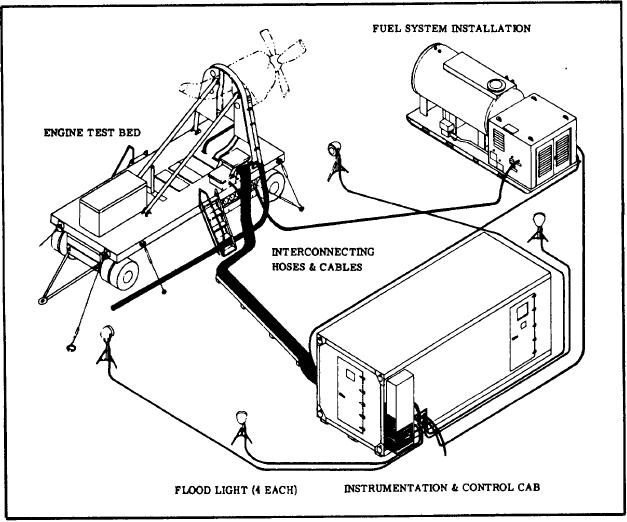

PORTABLE UNIVERSAL ENGINE

thermostats, alarm gongs, spurt and flood push

RUNUP TEST SYSTEMS

buttons, and pressure-operated switches. For

complete fire control coverage, the CO2 system

There are several different models of universal

is electrically linked to the interlock system and

test cells in use. Figures 10-20, 10-21, 10-22, and

pressure linked to the main fuel line valve of the

10-23 show some of the more commonly used test

engine fuel supply.

Figure 10-21.-Turboprop engine test system.

10-25