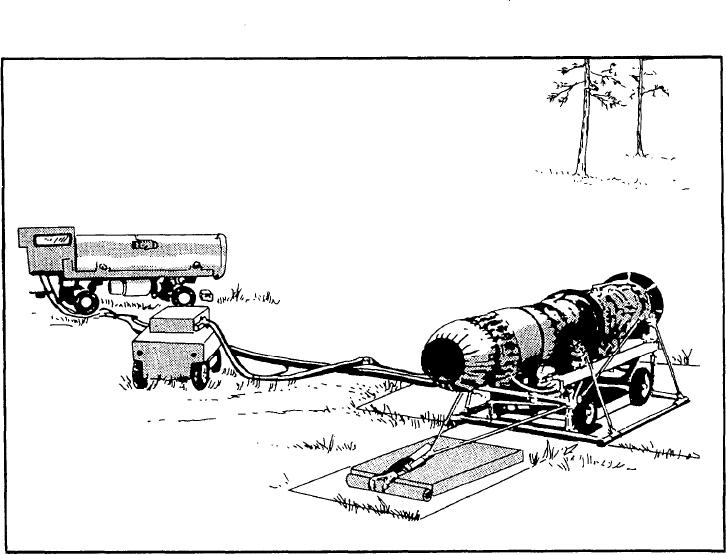

Figure 10-23.-Engine test and runup system.

cells that provide the aircraft maintenance

(not normally found in a test cell) needed to

satisfactorily conduct functional and performance

activities with a portable and universal system for

tests.

the operational and functional testing of jet air-

craft engines.

The console provides junction facilities to

These systems perform the basic functions

connect the cell power to the engine, a system for

of checking all the engine performance char-

remote control measurement of throttle position,

acteristics against the engine manufacturer's

a transmitter and receiver to indicate inlet guide

operational parameters, as approved by NAV-

vane position, and a dc electronic indicating

AIRSYSCOM. The test cells display engine

system for measuring nozzle position. A thermo-

temperatures, vibrations, fuel metering, fuel flow

couple type of anti-icing temperature indicator,

pressures, thrust, lube oil temperatures and

a starter circuit, and switches and cables necessary

pressure, compressor pressure, hydraulic oil

for operation of the engine and console under test

pressure, anti-ice pressure, turbine rpm, and

conditions are included in some consoles.

position indications such as nozzle and stator vane

Just as starting procedures vary with the

and throttle.

various types of engines, the controls and

NOTE: These test systems may be used at

instrumentation vary with different test cells.

any site location that has been provided

Checking the engine for proper operation consists

with adequate tie-downs (either concrete

primarily of reading engine instruments and then

embedded or buried expansion anchors).

comparing the deserved values with those given

by the manufacturer for specific engine condi-

Some engines require special testing consoles.

The console provides the electrical circuits

tions, atmospheric pressures, and temperatures.

10-27