The pickup assembly consists of electro-

housing. The power section assembly contains oil,

magnetic pickups mounted radially over the teeth

fuel, ignition, control, and cooling air systems.

It also has a compressor extension shaft to which

of the torque and reference shaft flanges. These

pickups produce electrical impulses at the passage

the torquemeter attaches.

of each exciter tooth. The pickups are displaced

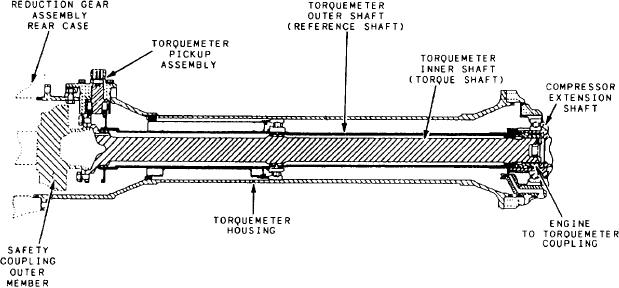

Torquemeter Assembly

so that the reference flange impulse from its

The torquemeter assembly is located between

pickup and the torque flange impulse from its

pickup are slightly out of phase at zero load.

the power section and reduction gear box

Because zero torque indications are not at the

assemblies. Its purpose is to transmit and measure

electrical zero of the indicator, both positive and

the shaft output from the power section to the

reduction gearbox assembly.

negative torque conditions are measured.

The torquemeter operates on the principle of

Reduction Gear Assembly

accurate measurement of torsional deflection

The reduction gear assembly changes the high

(twist) that occurs in any power transmitting shaft.

This torsional deflection is detected by magnetic

rpm, low torque of the turbine section to low rpm,

high torque necessary for efficient propeller

pickups. The deflection is measured electronically,

and displayed on the cockpit instrument panel in

operation. This change is made through a two-

stage reduction system of sun and planetary gears.

t e r m s of inch-pounds of torque, or shaft

See figure 8-5. The two stages of reduction

horsepower (SHP). The principle parts of the

provide an overall speed reduction of 13.54 to 1;

torquemeter assembly are shown in figure 8-4.

for example, when power section rpm is 13,820,

Two concentric shafts make up the torque-

the propeller shaft rpm is 1,020. The reduction

meter assembly. The inner shaft (torque shaft)

gear case also provides the drive and location to

carries the load and produces the measured twist.

mount the propeller and accessories. Accessories

The outer shaft (reference shaft for measuring

mounted on the case include a starter, generator,

purposes) is rigidly connected to the torque shaft

engine-driven compressor (EDC), oil pump, and

at the drive input end only. There are separate

flanges on both the torque and reference shafts

tachometer generator. The reduction gearbox

assembly also uses safety systems that we will

at the reduction gear assembly end. Rectangular

discuss next.

exciter "teeth" are machined in line on each

flange, which enable the pickups to detect the

TURBOPROP SAFETY SYSTEMS

relative displacement of the two flanges.

The complexity of the turboprop configura-

The torquemeter housing serves as a rigid

tion brought about the possibility of certain

lower support between the power unit and the

hazardous in-flight situations. Safety features

reduction gear assembly. It provides a mounting

have been designed into the system to activate

for the pickup assembly at the reduction gear end.

Figure 8-4.-Torquemeter assembly.

8-4