relay vital information concerning safety of flight.

Whenever practical, assembly design allows bulb

replacement in flight without the use of tools.

Most warning light designs have a push-to-test

feature or a test switch that lets you determine

if the bulb is good. The test switch energizes

various test relays, which, in turn, either provide

power or a ground circuit for energizing the lights.

This allows you to check the bulb without

operating the equipment.

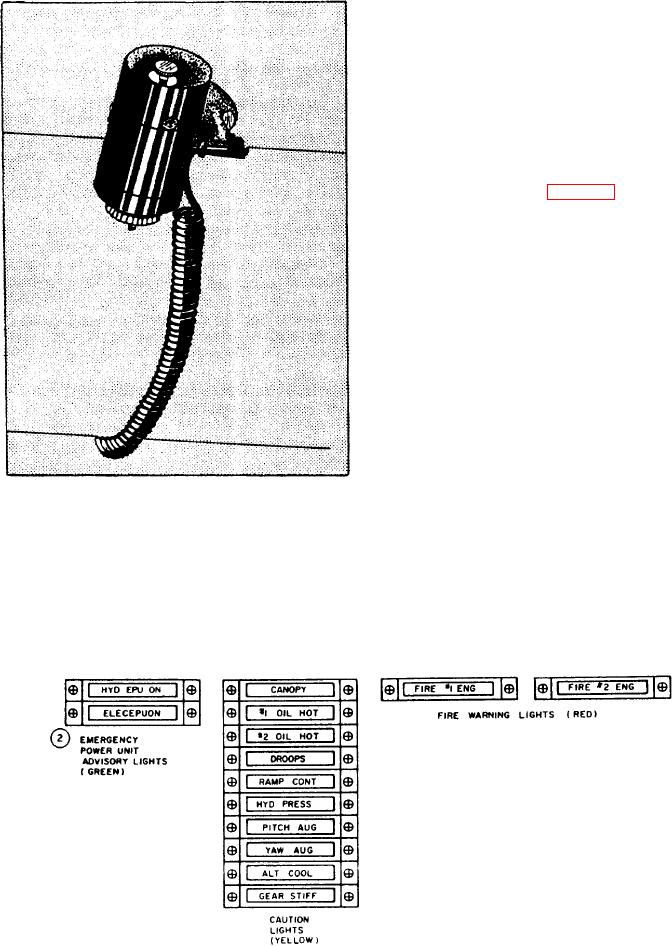

Legend-type lights (fig. 4-11) show specific

functions on the lens surface. They are prominent

on late model aircraft.

The warning lights are red. They warn the

crew of an emergency or unsafe operat-

ing condition, which requires immediate

corrective action.

The caution lights are yellow. They alert

the crew to a minor malfunction or im-

pending dangerous condition requiring attention,

but not necessarily immediate corrective action.

The advisory lights are green. They show

the crew a safe or normal configuration,

or a performance condition.

Figure 4-10.-Cockpit utility light.

Indicator lights must be bright enough to see

during daylight operation but not bright enough

to cause eyestrain at night. You obtain brilliance

The construction of indicator lights varies,

control by connecting resistors in the lighting

depending upon the particular job they perform.

circuit, and by placing dimmer caps on the lights.

Other ways of control are special adaption of edge

They mount in the aircraft where they are easily

noticeable when glowing. It is important that bulb

lighting, and special types of lenses that dim by

replacement be quick and easy since some lights

twisting the lens.

Figure 4-11.-Legend-type lights.

4-11