! Aluminum trailing edge cap

! Aluminum or polyurethane and nickel abrasion

leading edge strip

Additionally, rotary rudder blades may have

deicing provisions, such as electrothermal blankets that

are bonded into the blade's leading edge. or a neoprene

anti-icing guard embedded with electrical heating

elements.

Q4-17.

What is the main advantage of rotary-wing

aircraft over fixed-wing aircraft?

Q4-18.

What are the three types of landing gear used

on helicopters?

Q4-19.

The directional control and antitorque action

of the helicopter is provided by what group?

AIRCRAFT HYDRAULIC SYSTEMS

LEARNING OBJECTIVE:

Identify the

components of aircraft hydraulic systems and

recognize their functions.

The aircraft hydraulic systems found on most naval

aircraft perform many functions. Some systems

operated by hydraulics are flight controls, landing gear,

speed brakes, fixed-wing and rotary-wing folding

mechanisms, auxiliary systems, and wheel brakes.

Hydraulics has many advantages as a power source

for operating these units on aircraft.

! Hydraulics combine the advantages of

lightweight, ease of installation, simplification

of inspection, and minimum maintenance

requirements.

! Hydraulics operation is almost 100-percent

efficient, with only a negligible loss due to

fluid friction.

However, there are some disadvantages to using

hydraulics.

! The possibility of leakage, both internal and

external, may cause the complete system to

become inoperative.

! Contamination by foreign matter in the system

can cause malfunction of any unit. Cleanliness

in hydraulics cannot be overemphasized.

COMPONENTS OF A BASIC SYSTEM

Basically, any hydraulic system contains the

following units:

! A reservoir to hold a supply of hydraulic fluid

! A pump to provide a flow of fluid

! Tubing to transmit the fluid

! A selector valve to direct the flow of fluid

! An actuating unit to convert the fluid pressure

into useful work

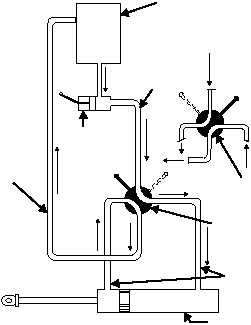

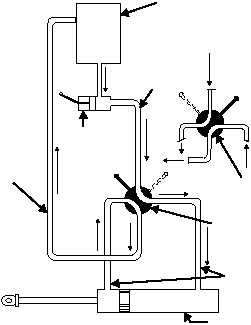

A simple system using these essential units is

shown in figure 4-21.

You can trace the flow of fluid from the reservoir

through the pump to the selector valve. In figure 4-21,

the flow of fluid created by the pump flows through the

valve to the right end of the actuating cylinder. Fluid

pressure forces the piston to the left. At the same time,

the fluid that is on the left of the piston is forced out. It

goes up through the selector valve and back to the

reservoir through the return line.

When the selector valve is moved to the position

indicated by the dotted lines, the fluid from the pump

flows to the left side of the actuating cylinder.

Movement of the piston can be stopped at any time

simply by moving the selector valve to neutral. When

the selector valve is in this position, all four ports are

closed, and pressure is trapped in both working lines.

4-19

ANF0421

PRESSURE

LINE

SELECTOR VALVE

IN "DOWN"

POSITION

RETURN

LINE

SELECTOR VALVE

IN "UP"

POSITION

WORKING

LINES

HAND

PUMP

ACTUATING

UNIT

RESERVOIR

Figure 4-21.—Basic hydraulic system, hand pump operated.