level of cleanliness must be maintained when working

on hydraulic components.

Only approved fill stand units are used to service

naval aircraft hydraulic systems. By following a few

basic rules, you can service hydraulic systems safely

and keep contamination to a minimum.

! Never use fluid that has been left open for an

undetermined period of time. Hydraulic fluid

that is exposed to air will absorb dust and dirt.

! Never pour fluid from one container into

another.

! Use only approved servicing units for the

specific aircraft.

! Maintain hydraulic fluid-handling equipment

in a high state of cleanliness.

! Always make sure you use the correct

hydraulic fluid.

Contamination of the hydraulic system may be

caused by wear or failure of hydraulic components and

seals. This type of contamination is usually found

through filter inspection and fluid analysis. Continued

operation of a contaminated system may cause

malfunctioning

or

early

failure

of

hydraulic

components.

Q4-20.

What are two disadvantages of a hydraulic

system?

Q4-21.

On a basic hydraulic system, what is the

purpose of the selector valve?

Q4-22.

On a basic hydraulic system, what is the

purpose of the actuating unit?

Q4-23.

Define hydraulic contamination.

PNEUMATIC SYSTEMS

LEARNING OBJECTIVE:

Identify the

components of aircraft pneumatic systems and

recognize their functions.

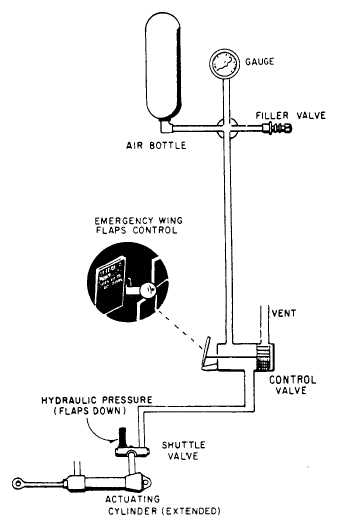

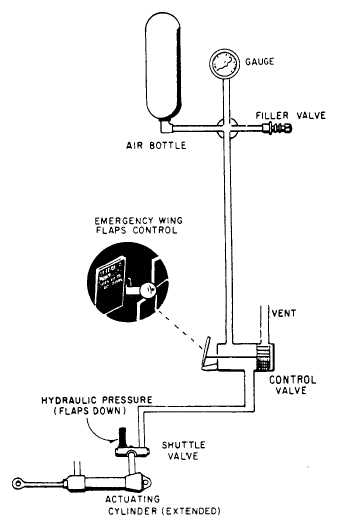

There are two types of pneumatic systems currently

used in naval aircraft. One type uses storage bottles for

an air source, and the other has its own air compressor.

Generally, the storage bottle system is used only for

emergency operation. See figure 4-23. This system has

an air bottle, a control valve in the cockpit for releasing

the contents of the cylinders, and a ground charge

(filler) valve. The storage bottle must be filled with

compressed air or nitrogen prior to flight. Air storage

cylinder pneumatic systems are in use for emergency

brakes, emergency landing gear extension, emergency

flap extension, and for canopy release mechanisms.

When the control valve is properly positioned, the

compressed air in the storage bottle is routed through

the shuttle valve to the actuating cylinder.

NOTE:

The shuttle valve is a pressure-operated

valve that separates the normal hydraulic system from

the emergency pneumatic system. When the control

handle is returned to the normal position, the air

pressure in the lines is vented overboard through the

vent port of the control valve.

The other type of pneumatic system in use has its

own air compressor. It also has other equipment

necessary

to

maintain

an

adequate

supply

of

compressed air during flight. Most systems of this type

must be serviced on the ground prior to flight. The air

4-21

ANf0423

Figure 4-23.—Emergency pneumatic system.