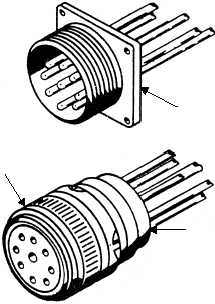

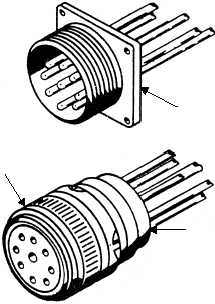

assemblies are coupled by means of a coupling nut.

Each consists of an aluminum shell containing an

insulating

insert

that

holds

the

current-carrying

contacts. The plug is usually attached to the cable end,

and is the part of the connector on which the coupling

nut is mounted. The receptacle is the half of the

connector to which the plug is connected. It is usually

mounted on a part of the equipment. One type of

connector commonly used in aircraft electrical systems

is shown in figure 5-19.

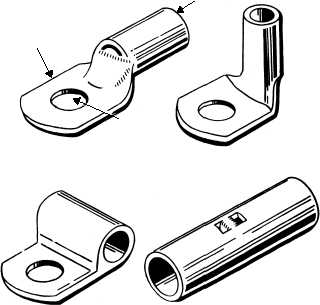

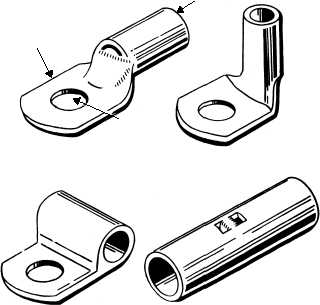

TERMINALS

Since most aircraft wires are stranded, it is

necessary to use terminal lugs to hold the strands

together. This allows a means of fastening the wires to

terminal studs. The terminals used in electrical wiring

are either of the soldered or crimped type. Terminals

used in repair work must be of the size and type

specified in the applicable maintenance instruction

manual. The crimped-type terminals are generally

recommended for use on naval aircraft. Soldered-type

terminals are usually used in emergencies only.

The basic types of solderless terminals are shown

in figure 5-20. They are the straight, right angle, flag,

and splice types. There are variations of these types.

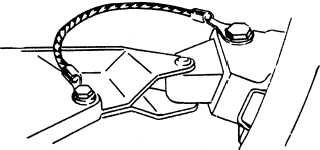

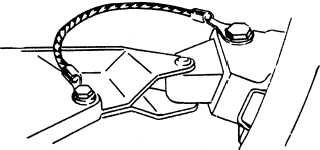

BONDING

When you connect all the metal parts of an aircraft

to complete an electrical unit, it is called bonding.

Bonding connections are made of screws, nuts,

washers, clamps, and bonding jumpers. Figure 5-21

shows a typical bonding link installation.

An aircraft can become highly charged with static

electricity while in flight. If the aircraft is improperly

bonded, all metal parts do not have the same amount of

static charge. A difference of potential exists between

the various metal surfaces. If the resistance between

insulated metal surfaces is great enough, charges can

accumulate. The potential difference could become

high enough to cause a spark. This constitutes a fire

hazard and also causes radio interference. If lighting

strikes an aircraft, a good conducting path for heavy

current is necessary to minimize severe arcing and

sparks.

Bonding

also

provides

the

necessary

low-

resistance

return

path

for

single-wire

electrical

systems. This low-resistance path provides a means of

bringing the entire aircraft to the earth's potential when

it is grounded.

5-14

ANF0519

RECEPTACLE

ASSEMBLY

COUPLING

NUT

PLUG SOCKET

ASSEMBLY

Figure 5-19.—Connector assembly.

ANF0520

TOUGUE

BARREL

TERMINAL

HOLE

STRAIGHT

RIGHT ANGLE

FLAG

SPLICE

Figure 5-20.—Basic types of solderless terminals.

ANF0521

Figure 5-21.—Typical bonding link installation.