Torque all parts to the recommended values, and

align holes before you attempt to proceed with the

safetying operation. Never overtorque or loosen a

torqued nut to align safety wire holes.

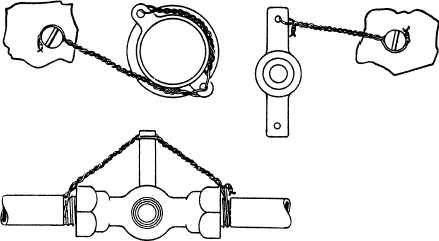

Oil Caps, Drain Cocks, and

Valves

These units are safety wired as shown in figure

5-24. In the case of the oil cap, the wire is anchored to

an adjacent fillister head screw. This system applies to

any other unit that must be safety wired individually.

Ordinarily, anchorage lips are conveniently located

near these individual parts. When this provision is not

made, the safety wire is fastened to some adjacent part

of the assembly.

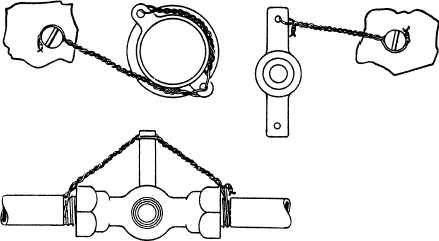

Electrical Connectors

Under conditions of severe vibration, the coupling

nut of a connector may vibrate loose. With sufficient

vibration, the connector could come apart. When this

occurs, the circuit carried by the cable opens. The

proper protective measure to prevent this occurrence is

by safety wiring, as shown in figure 5-25. The safety

wire should be as short as practicable. It must be

installed in such a manner that the pull on the wire is in

the direction that tightens the nut on the plug.

Turnbuckles

After you adjust a turnbuckle properly, safety it.

There are several methods of safetying turnbuckles.

Only two of these methods have been adopted by the

military services. These methods are shown in views

5-17

ANF0523

OIL CAPS

DRAIN COCKS

VALVES

NOTE:

THE SAFETY WIRE IS

SHOWN INSTALLED

FOR RIGHT-HAND

THREADS. THE SAFETY

WIRE IS ROUTED IN THE

OPPOSITE DIRECTION

FOR LEFT-HAND THREADS.

Figure 5-24.—Safety wiring oil caps, drain cocks, and valves.

ANF0525

RECEPTACLE

BULKHEAD

OR

PLATE

STANDARD FILLISTER

HEAD SCREW

(DRILLED HEAD)

PLUG

ADAPTER

Figure 5-25.—Safety wiring attachment for plug connectors.