Turnbuckles are fitted in the cable assembly for the

purpose of making minor adjustments in cable length

and for adjusting cable tension. One of the terminals

has right-hand threads and the other has left-hand

threads. The barrel has matching right- and left-hand

internal threads. The end of the barrel with the left-hand

threads can usually be identified by a groove or knurl

around that end.

When installing a turnbuckle in a control system, it

is necessary to screw both of the terminals an equal

number of turns into the barrel. It is also essential that

you screw both turnbuckle terminals into the barrel

until not more than three threads are exposed.

After you adjust a turnbuckle properly, it must be

safetied. We will discuss the methods of safetying

turnbuckles later in this chapter.

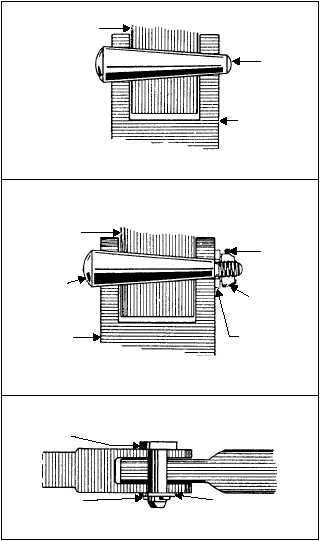

TAPER PINS

Taper pins are used in joints that carry shear loads

and where the absence of clearance is essential. See

figure 5-17. The threaded taper pin is used with a taper

pin washer and a shear nut if the taper pin is drilled. Use

a self-locking nut if the taper pin is undrilled. When a

shear nut is used with the threaded taper pin and

washer, the nut is secured with a cotter pin.

FLAT HEAD PINS

The flat head pin is used with tie-rod terminals or

secondary controls, which do not operate continuously.

The flat head pin should be secured with a cotter pin.

The pin is normally installed with the head up. See

figure 5-17, view C. This precaution is taken to

maintain the flat head pin in the installed position in

case of cotter pin failure.

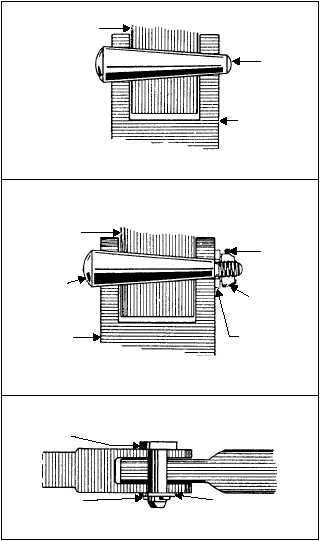

FLEXIBLE CONNECTORS/CLAMPS

Some of the most commonly used clamps are

shown in figure 5-18. When installing a hose between

two duct sections, the gap between the duct ends should

be one-eighth inch minimum to three-fourths inch

maximum. When you install the clamps on the

connection, the clamp should be one-fourth inch

minimum from the end of the connector. Misalignment

between the ducting ends should not exceed one-eighth

inch maximum.

Marman type clamps, commonly used in ducting

systems, should be tightened to the torque value

indicated on the coupling. Use the torque value as

specified on the clamp or in the applicable maintenance

instruction manual.

Q5-9.

What are five fasteners that are included in

the category of miscellaneous fasteners?

AIRCRAFT ELECTRICAL SYSTEM

HARDWARE

LEARNING OBJECTIVE:

Identify the

special

hardware

found

in

an

aircraft's

electrical system.

An important part of aircraft electrical maintenance

is determining the correct type of electrical hardware

for a given job. You must become familiar with wire

and cable, connectors, terminals, and bonding.

5-12

ANF0517

STATIONARY

MEMBER

STATIONARY

MEMBER

PLAIN

TAPER

PIN

MOVABLE

MEMBER

MOVABLE

MEMBER

COTTER

PIN

COTTER

PIN

CASTELLATED

NUT

TAPER

PIN

WASHER

THREAD

TAPER

PIN

FLAT

HEAD

PIN

WASHER

A. PLAIN TAPER PIN INSTALLED

B. THREADED TAPER PIN INSTALLED

C. FLAT HEAD PIN INSTALL

Figure 5-17.—Types of aircraft pins.