pressure or return port of the brake line. Two springs are

provided. The large spring, referred to in the illustration

as the plunger spring, provides “feel” to the brake pedal.

The small spring returns the spool to the OFF position.

When the plunger is depressed, the large spring

moves the spool, which closes off the return port and

opens the pressure port to the brake line. When the

pressure enters the valve, fluid flows to the opposite end

of the spool through a hole. The pressure pushes the

spool back far enough toward the large spring to close

the pressure port, but not open the return port. The valve

is then in the static condition. This movement partially

compresses the large spring, giving “feel” to the brake

pedal. When the brake pedal is released, the small spring

moves the spool back, opening the return port. This

action allows fluid pressure in the brake line to flow out

through the return port.

Maintenance of the sliding spool brake control

valve is limited to checking the action of the plunger.

This is done by manually depressing the plunger until it

bottoms, and then releasing it suddenly. If the plunger

remains depressed (does not snap out), the valve is

binding at the spool and sleeve. If binding occurs, the

valve should be replaced. Disassembly of the valve is

not permitted at the organizational level of maintenance,

but may be performed by an intermediate or higher level

activity.

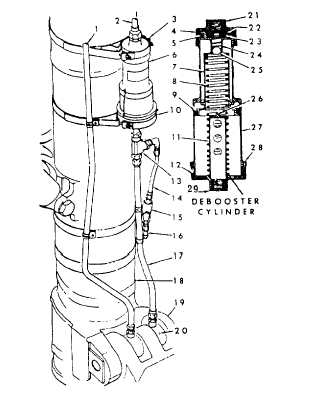

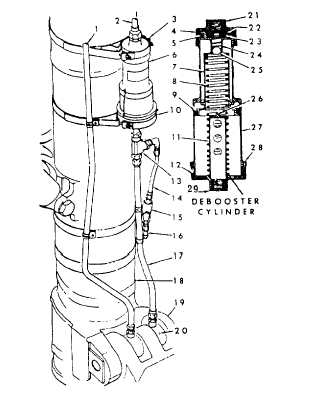

Brake Debooster Cylinder

In some power brake control valve systems,

debooster cylinders are used in conjunction with the

power brake control valves. These units are generally

used on aircraft equipped with a high-pressure hydraulic

system and low-pressure brakes. The purpose of the

brake debooster cylinder is to reduce the pressure to the

brake and increase the volume of fluid flow. Figure

12-29 shows a typical debooster cylinder installation.

The unit is being mounted on the landing gear shock

strut in the line between the control valve and the brake.

The schematic diagram in the illustration shows the

internal parts of the cylinder.

When the brake is applied, fluid under pressure

enters the inlet port to act on the small end of the piston.

The ball check prevents the fluid from passing through

the shaft. Force is transmitted through the small end of

the piston to the large end of the piston. As the piston

moves downward in the housing, a new flow of fluid is

created from the large end of the housing through the

outlet port to the brake. Because the force from the small

piston head is distributed over the greater area of the

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

Emergency system

pressure line

Main brake pressure line

Upper support clamp

Packing

Packing

Debooster cylinder

assembly

Piston

Piston return spring

Packing

Lower support clamp

Riser tube

Packing

Tee fitting

Brake line (to pressure

15.

16.

17.

18.

19.

20.

21.

22. Snapring

23. Spring retainer

24. Valve spring

25. Ball

26. Ball pedestal

27. Barrel

28. Lower cud cap

Brake pressure-relief

valve

Overflow line

Brake tine (debooster to

shuttle valve)

Shock strut

Torque link

Brake shuttle valve

Inlet port

relief valve)

29. Outlet port

Figure 12-29.-Brake debooster cylinder.

large piston head, pressure at the outlet poet is reduced.

At the same time, a greater volume of fluid is displaced

by the large piston head than that used to move the small

piston head.

Normally, the brake will be fully applied before the

piston has reached the lower end of its travel. However,

if the piston fails to meet sufficient resistance to stop it

(due to a loss of fluid from the brake unit or connecting

lines), the piston will continue to move downward until

the riser unseats the ball check valve in the hollow shaft.

With the ball check valve unseated, fluid from the power

control valve will pass through the piston shaft to

12-34