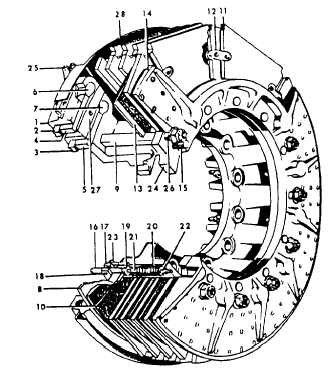

MULTIPLE/TRIMETALLIC DISC BRAKES

Multiple disc brakes are heavy-duty brakes

designed for use with power brake control valves or

power boost master cylinders. The brake assembly

consists of a bearing carrier bearings and retaining nut;

the annular actuating piston; and the heat stack, which

is composed of a pressure plate, rotating discs (rotors),

stationary discs (stators) and backup plate, an automatic

adjuster, retracting springs, and various other

components.

Regulated hydraulic pressure is applied through the

automatic adjuster to a chamber in the bearing carrier.

The bearing carrier is bolted to the shock strut axle

flange and serves as a housing for the annular actuating

piston. Hydraulic pressure forces the annular piston to

move outward, compressing the rotating discs, which

are keyed to the landing wheel, and the stationary discs,

which are keyed to the bearing carrier. The resulting

friction causes a braking action on the wheel and tire

assembly.

When the hydraulic pressure is relieved, the

retracting springs force the actuating piston to retract

into the housing chamber in the bearing carrier. The

hydraulic fluid in the chamber is forced out by the return

of the annular actuating piston, and is bled through the

automatic adjuster to the return line. The automatic

adjuster traps a predetermined amount of fluid in the

brake–an amount just sufficient to give correct

clearances between the rotating discs and stationary

discs. See figure 12-33.

The trimetallic disc type brakes are used on most

naval aircraft. They operate on the same basic principle

as the multiple disc brakes and will be discussed in detail

later in this chapter.

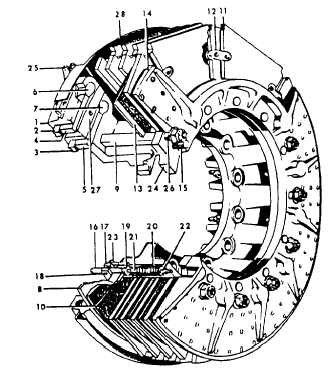

SEGMENTED ROTOR BRAKES

Segmented rotor brakes are heavy-duty brakes,

especially adapted for use with high-pressure hydraulic

systems. These brakes may be used with either power

brake control valves or power boost master cylinders.

Braking is accomplished by means of several sets of

stationary, high-friction type of brake linings making

contact with rotating (rotor) segments. A cutaway view

of the brake is shown in figure 12-34. As you can see,

the segmented rotor brake is very similar to the multiple

disc type, described in the previous section.

The brake assembly consists of a carrier, two

pistons and piston cup seals, a pressure plate, an

auxiliary stator plate, rotor segments, stator plates, a

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

Carrier assembly

Piston cup (outer)

Piston cup (inner)

Piston (outer)

Piston (inner)

Piston end (outer)

Piston end (inner)

Pressure plate

Stator drive sleeve

Auxiliary stator and

lining assembly

Rotor segment

Rotor link

Stator plate

Backing plate

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

Torque pin

Adjuster pin

Adjuster clamp

Adjuster screw

Adjuster washer

Adjuster return spring

Adjuster sleeve

Adjuster nut

Clamp holddown

assembly

Shim

Bleeder screw

Drive sleeve bolt

Dust cover (inner)

Dust cover (outer)

Figure 12-34.-Segmented rotor brake–cutaway view.

compensating shim, automatic adjusters, and a backing

plate.

BRAKE SYSTEM MAINTENANCE

Learning Objective: Identify the two primary

brake systems and the checks required to make

sure these systems operate properly.

Brake systems are designed to retard or to stop

aircraft motion on the ground. They also aid in

controlling the direction of the aircraft while it is taxiing.

Provisions exist for applying either one or both brakes

12-39