The nylon barrier consists of three to four coats of

nylon applied hot by brush, swab, or spray. The purpose

of the nylon barrier is to keep fuel from diffusing

through the cell wall.

The retainer consists of Buna N coated square-

woven fabric (cotton or nylon) or cord fabric. The

purpose of the retainer ply or plies is to lend strength to

the fuel cell and provide protection for the nylon fuel

barrier.

NYLON-TYPE BLADDER CELLS (PLIO-

CEL).—Nylon bladder cells differ in construction and

material from the Buna N rubber cells. This type of cell

may be identified by the trade name “Pliocel” stenciled

on the outside of the cell. The Pliocel construction

consists of two layers of nylon woven fabric laminated

with three layers of transparent nylon film.

The repair of this type of cell must be accomplished

by entirely different methods and with different

materials. The adhesive and Buna N rubber used to

repair the rubber-type bladder cell cannot be used on the

nylon-type cell.

INTEGRAL FUEL CELLS REPAIR

Integral fuel cells are usually contained in the wing

structure; however, in some aircraft integral fuel cells

are built into the fuselage. An integral cell is a part of

the aircraft structure that has been built in such a reamer

that after the seams, structural fasteners, and access

doors have been properly sealed, it will hold fuel without

leaking. This type of construction is usually referred to

as a “wet wing.”

Usually, the cell area is located between two spars,

and is capped on the ends by sealed end ribs. The skin

covering may be standard riveted sheet or may be milled

from a solid plate of aluminum alloy. The milled skins

are usually bolted in place instead of being riveted.

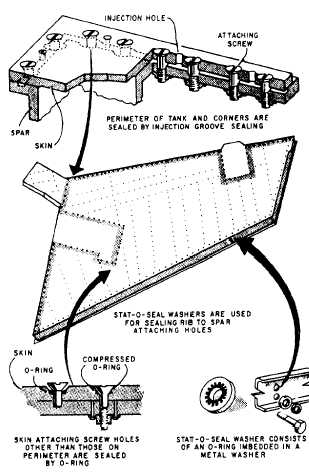

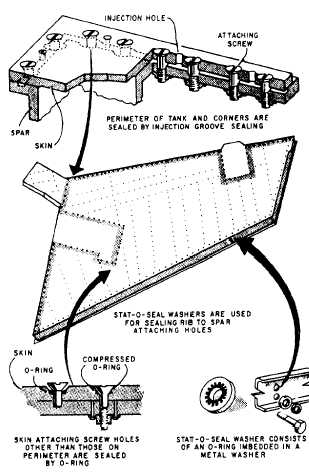

The wing mating surfaces are built to extremely

close tolerances to allow for proper sealing. The sealing

of these mating surfaces is attained by using gaskets or

sealants, or a combination of both. In most cases, the

perimeter of the cell is sealed by using a nonhardening

sealant that is injected into a groove machined in one

structural member along the mating surface. The

attachment screws and bolts are sealed by placing

O-ring seals under the heads. Protruding bolt heads are

sealed by special seals that consist of an O-ring

embedded in a metal washer. Figure 3-34 shows the

sealing of integral fuel cell screws and bolts.

Figure 3-34.—Sealing integral fuel cell screws and bolts.

Inspection

The inspection of integral fuel cells consists mainly

of a check for external leakage around skin joints, rivets,

screws, and bolts on every preflight inspection. The fuel

cell fittings and connections should also be inspected for

evidence of leakage. Fuel cell leaks are classified in the

following categories: slow seep, seep, heavy seep, and

running leak.

• SLOW SEEP.—The least severe leak classifi-

cation is the slow seep. This is a very slow fuel seepage

that wets a small area. Over a period of hours, the wetted

area may become larger. A slow seep, when wiped dry,

will not reappear in a short period of time.

• SEEP.—A seep is a fuel leak that reappears in less

than an hour (approximately) after it has been wiped dry.

• HEAVY SEEP.—A heavy seep is a fuel leak that

reappears immediately after it has been wiped dry.

3-47