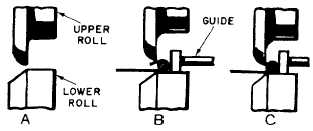

BEADING ROLLS.—Beading rolls are used for

turning beads (grooves) on tubing, cans, and buckets.

Beads may also be placed on sheet stock that is to be

welded. There are several different types of beading

rolls. Those shown in figure 13-41 are single bead

rolls. When you are beading, the groove should not

be made too deeply in a single rotation as this tends to

weaken the metal.

TURNING ROLLS.—Turning rolls are used for

turning an edge to receive a stiffening wire. When

you are turning an edge, rest the cylinder to be wired

on the lower wheel and press against the gauge. The

gauge is adjusted according to the size of wire to be

used. With the work set in place, bring the upper roll

down until it grips the metal. Turn the crank slowly

while you are holding the metal so that the metal will

feed into the rolls. Continue to press against the

guide. After the first revolution, gradually raise the

metal until it touches the outer face of the top roll.

Remove the stock by raising the top roll.

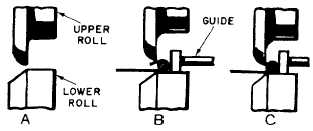

WIRING ROLLS.—Wiring rolls are used to

finish the wired edges prepared in the turning rolls.

To use the wiring rolls, you should adjust the top roll

so that it is directly above the point on the lower roll

where the beveled and flat surfaces meet, as shown in

view A of figure 13-42. Adjust the guide to the

position shown in view B, then bring the top roll down

so that it will turn the edge of the metal as shown in

view C.

Remove the stock from the machine by

raising the top roll.

CRIMPING ROLLS.—Crimping rolls are used

to make one end of a pipe smaller than the other so

that two sections may be slipped together, one end

into the other. A bead is placed on a pipe first, and

then it is crimped. The bead forms a shoulder to keep

the pipe from slipping too far into the adjoining

section.

BURRING ROLLS.—Burring is perhaps the

most difficult operation to perform on a rotary

machine. Before you place the work in the machine,

Figure 13-42.—Wiring operation.

make sure the cylinder or circular disc to be burred is

cut or formed as perfectly round as possible. Then

adjust the gauge on the machine so the space between

the inside of the upper roll and the gauge is set to the

width of the burr. Next, place the object between the

rolls and against the gauge. Then you should lower

the upper roll until it scores the material slightly.

Turn the crank slowly to allow the metal to slide

between thumb and fingers. Apply a slight upward

pressure as the metal passes between the rolls. After

the first revolution, lower the top roll and again pass

the metal between the rolls. Repeat this process,

raising the edge slightly with each complete

revolution of the material, until the edge has been

burred to the proper angle.

RIVETING PROCEDURES

You must use your knowledge, ability, and

experience to plan an aircraft structural repair that

involves riveting.

Each rivet must be selected and

driven in a precise manner to meet the riveting

specification. Some of the specifications are rivet

spacing and edge distance, diameter of the rivet hole,

aerodynamic smoothness, and size of the rivet

bucktail. These can be accomplished only through

determination, practice, and accurate manipulation of

all layout and riveting equipment.

Rivet Selection

The following rules should govern your selection

and use of rivets:

1. Replacements must not be made with rivets of

lower strength material unless they are larger than

those removed. For example, a rivet of 2024

aluminum alloy should not be replaced by one made

of 2017 aluminum alloy unless the 2017 rivet is a size

larger. Similarly, when 2117 rivets are used to replace

2017 rivets, the next larger size should be used.

2. When rivet holes become enlarged, deformed,

or otherwise damaged, you should use the next larger

size as replacement.

3. Countersunk-head rivets should be replaced

by rivets of the same type and degree of countersink,

either AN426 or MS20426.

4. All protruding-head rivets should be replaced

with universal-head rivets, either AN470 or

MS20470.

5. Rivets less than three thirty-seconds of an inch

in diameter should not be used for any structural parts,

13-26