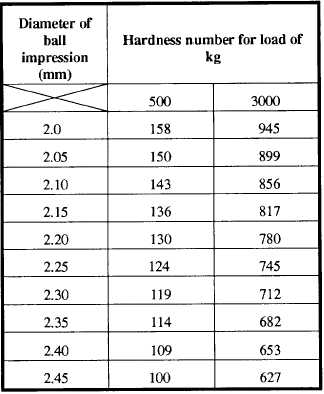

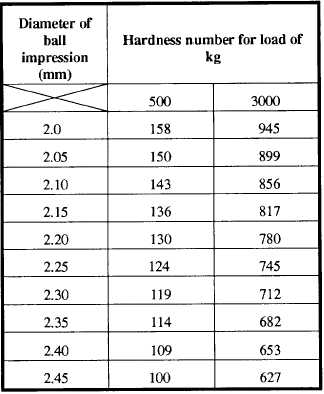

Table 1-3.—Portion of Conversion Table Furnished with Brinell

Tester

the microscope. After measuring the diameter of the

impression, the measurement is converted into the

Brinell hardness number on the conversion table

furnished with the tester. A portion of the conversion

table is shown in table 1-3.

ROCKWELL TESTER

The Rockwell hardness tester, shown in figure 1-27,

measures the resistance to penetration as does the

Brinell tester, but instead of measuring the diameter of

the impression, the Rockwell tester measures the depth,

and the hardness is indicated directly on a dial attached

to the machine. The more shallow the penetration, the

higher the hardness number.

Two types of penetrators are used with the Rockwell

tester–a diamond cone and a hardened steel ball. The

load that forces the penetrator into the metal is called the

“major load,” and is measured in kilograms. The results

of each penetrator and load combination are reported on

separate scales, designated by letters. The penetrator,

the major load, and the scale vary with the kind of metal

being tested.

For hardened steels, the diamond penetrator is used,

the major load is 150 kilograms, and the hardness is read

on the C scale. When this reading is recorded, the letter

C must precede the number indicated by the pointer. The

C-scale setup is used for testing metals ranging in

hardness from C-20 to the hardest steel (usually about

C-70). If the metal is softer than C-20, the B-scale setup

is used. With this setup, the 1/16-inch ball is used as a

penetrator, the major load is 100 kilograms, and the

hardness is read on the B scale.

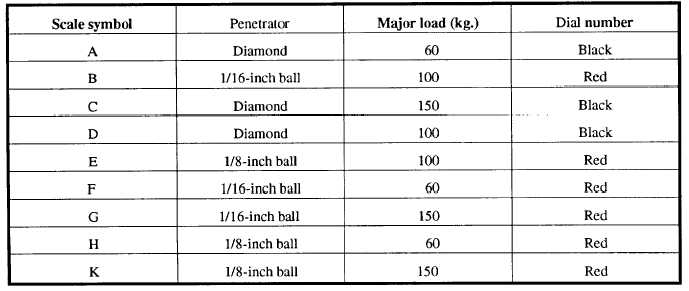

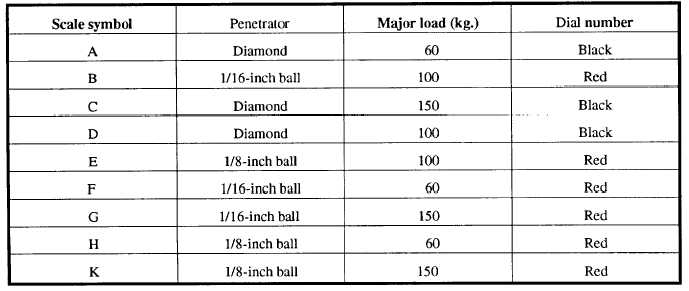

In addition to the C and B scales, there are other

setups for special testing. The scales, penetrators, major

loads, and dial numbers are listed in table 1-4. The dial

Table 1-4.—Standard Rockwell Hardness Scales

1-37